Tolerance Analysis Report

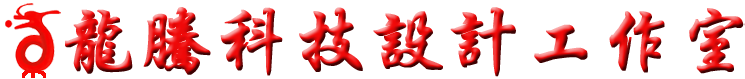

1.手持裝置大部分都有放置 mic 如是接觸式因有上下殼與 pcb 件的製造公差,如 mic 與 pcb 預壓量不足,會有產生接觸性的問題.

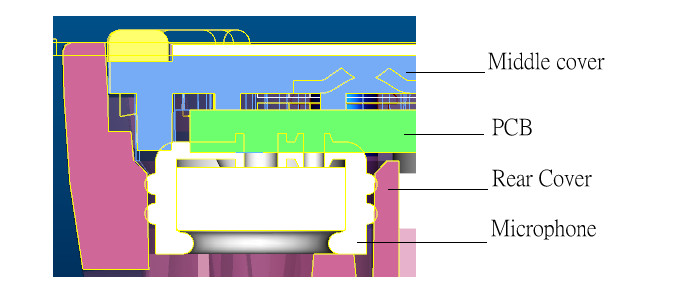

1. mic : 2.85 ±0.2

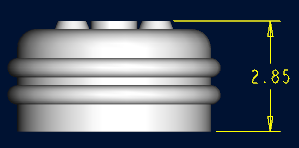

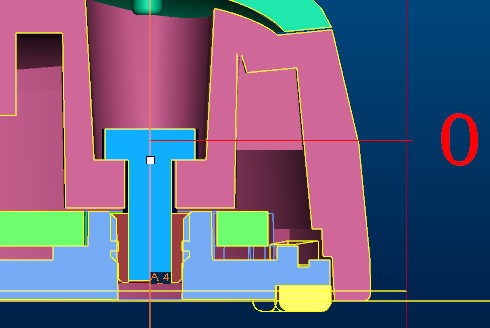

2. Rear Cover : 3.7 ±0.1

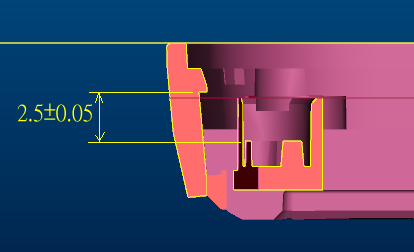

3. Real cover of mic hole bottom to hook distance is 2.5 ±0.05

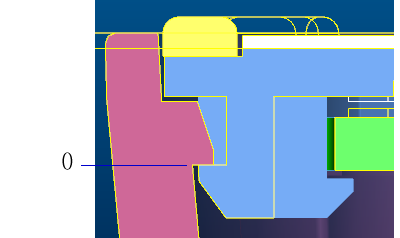

4. Middle cover and rear cover hook distance is 0 .

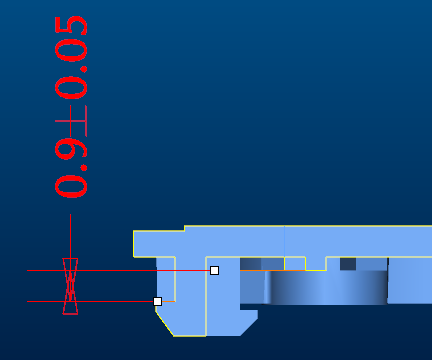

5. Middle cover of Hook to base on PCB boss distance is 0.9 ±0.05

6. Pcb thickness is 1.0 ±0.1 mm

Verify

Tolerance analysis report: TA_10012008

Analysis

Worst Case : Gap Max= 2.4+0.2=2.6 mm Min=2.4-0.2=2.2 mm

Statistical : Gap Max=2.4+0.12=2.52mm Min=2.4-0.12=2.28 mm

Because microphone compressed working height is 2.45 ±0.1 mm , and general condition that cell phone has increase height from as around some components forced or deform caused mic contact pcb trend for bigger space , So it can consider actually measure pcb and mic hole bottom distance as critical over normal dimension 2.43 mm (Mean).

2. Mic and PCB of PAD after assmeble that result has shift position , It must concerned as short issue , this will be analysis X,Y axis

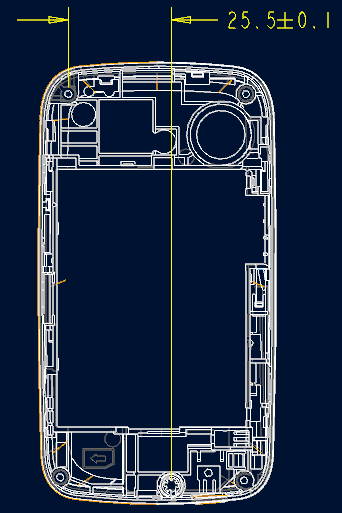

Think assembly relationship

1.Mic put on Rear Cover

2. pcb put on middle cover

3. Middle cover sub assemble into the Rear Cover sub assembly

So loop is

Pcb pad center-> Pcb hole center ->pcb hole of radius -> Pcb hole and middle cover boss of gap -> middle cover boss of radius ->middle cover boss center -> Rear cover boss center -> D Cover mic hole center

About Y axis

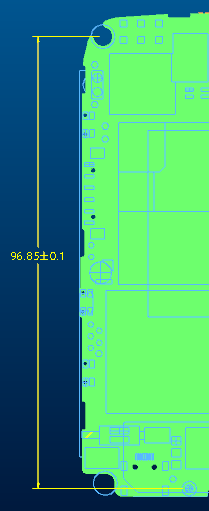

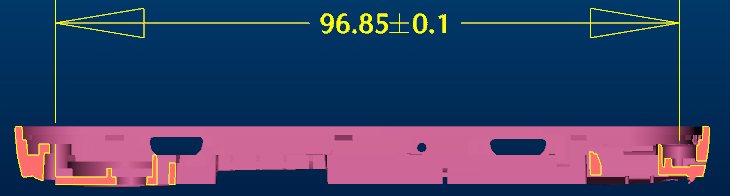

1.Pcb pad center and Pcb hole center distance is 96.85 ±0.1 mm

2. Pcb hole of radius is R2±0.05

3. Pcb hole and middle cover boss of gap

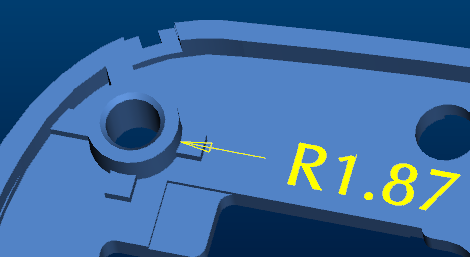

Gap=R2-R1.87=0.13

4. middle cover boss of radius is R1.87 ±0.05 mm

5.Middle cover boss center to Rear cover boss center distance is 0 mm

6. Rear cover boss center to Rear cover mic hole center by Y axis is 96.85 ± 0.1 mm

Verify

Tolerance analysis report: TA_10032008

Pro/E CETOL analysis : Report

Analysis

Worst Case : Mic center shift = ± 0.3 mm

Statistical : Mic center shift = ± 0.16 mm

About X axis

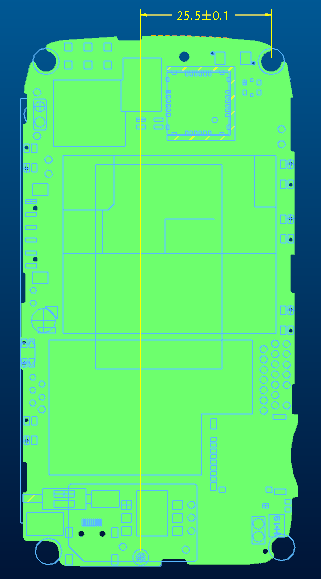

1.Pcb pad center and Pcb hole center distance is 25.5 ± 0.1 mm

2. Pcb hole of radius is R2±0.05 mm

3. Pcb hole and middle cover boss of gap is 0.13 mm

4. middle cover boss of radius is R1.87 ±0.05 mm

5.Middle cover boss center to Rear cover boss center distance is 0 mm

6. Rear cover boss center to Rear cover mic hole center by X axis is 25.5 ± 0.1 mm

Verify

Tolerance analysis report: TA_10062008

Analysis

Worst Case : Mic center shift = ± 0.3 mm

Statistical : Mic center shift = ± 0.16 mm

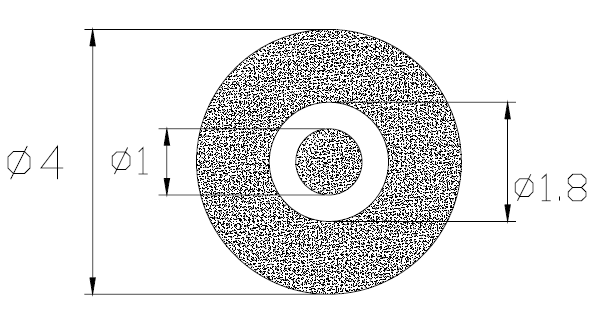

According to vendor of technical datasheet from list

Recommended electrode pattern

If Layout manufacture tolerance is ± 0.1 mm , So inner circle pad and outer circle one side space is (1.8-1)/2 = 0.4 mm and if plus tolerance 0.1 mm (inner pad and outer pad) that is 0.4 mm - 0.1 mm = 0.3 mm .

Conclusion

That can observer if use worst case that has short issue ( The mean is mic center pad shift touch PCB outer pad of mic ) , If for statistical model this is safe distance .

網內資料: