![]()

|

|

|

|

Stepping up the Sustainability of Entire Product Lines: Start with One Exemplary Product By Pamela J. Gordon, Technology Forecasters Store by 2011/01/22 Business rewards from designing “sustainable” electronic products—(otherwise known as products with “design-for-environment” (DfE) principles) abound. Manufacturers purchase fewer components/materials, assemble products in shorter time, and ship smaller/lighter products. Sales and marketing get to promote a more efficient, competitive product. Retailers economize on shelf space. Customers save operating costs and reduce packaging waste. And the products are worth more after they have been used. However, even though DfE principles themselves are not complicated, some electronics companies need a kick-start to deploying DfE throughout their product lines. One way to start is to design one “DfE-exemplary” product.Designing DfE-exemplary products can be a positive initial move toward stepping up the sustainability of entire product lines and entire industries. In this column I describe the characteristics of DfE-exemplary products, offer examples, discuss the pros and cons, and offer suggestions for overcoming any objections to the idea. Characteristics of DfE-Exemplary Products A DfE-exemplary product benefits from sustainable thinking during product concept (including developing the business model); product design, manufacturing, and distribution; and planning for reuse and end of life. Table 1 lists the main categories of a DfE checklist along with sample questions within each category. A DfE-exemplary product should result in a “yes” answer to most of these questions.

Table 1. Main Categories of a DfE Checklist, with Examples

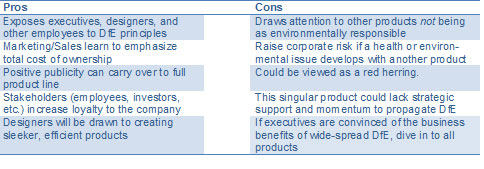

For the full Design-for-Environment Checklist, contact Technology Forecasters Inc. Debate about Carbon Off-sets Some companies’ DfE-exemplary products include carbon offsets to arrive at or close to “carbon neutral.” Motorola’s “MOTOCUBO” is touted as the world’s first BFR/PVC-free, CarbonFreeR certified phone. The phone is certified carbon neutral by Carbonfund.org. According to the press release, “through this partnership Motorola will offset all the carbon emitted in the manufacture, distribution and use of the cellular phone with investments in preservation, reforestation and renewable energy project.” Most DfE-exemplary products, however, minimize the product’s own environmental footprint – during all phases of the product’s life—and do not leverage carbon offsets. My recommendation is to go as far as possible reducing environmental impact before considering offsets. If market research indicates that your product’s market share will be significantly enhanced by certifying as carbon neutral, do strongly consider making these investments. Emphasize Overall Cost of Ownership Many of the design strategies represented in the DfE checklist reduce the cost of materials, manufacturing, and shipping. Now and then, however, a smart DfE design will leverage a component or subsystem whose purchase price is higher, but whose performance and/or synergy with other parts reduces the total cost of ownership. One example is choosing solid state drives instead of hard drives, which yields approximately five times the reliability and energy efficiency of a hard drive. It can be lighter and generate less heat as well. However, the solid state drive’s purchase price is currently quite a bit higher than standard hard drives; we are confident that in time, costs and prices will come down. In the meantime, several tech companies’ DfE-exemplary products do use solid state drives . Their Marketing and Sales groups position these products to customers as providing long-term lower cost of ownership due to lower energy consumption, higher reliability, and other factors. Sometimes a more expensive component can eliminate the need for purchasing several other components. For example, a component that generates less heat can alleviate the need for fans and heat sinks; this can reduce the size, weight, and reliability of the product as well. So, do consider choosing for your DfE-exemplary product elements that may increase purchase price but reduce operating costs. Choose your market for the product based on value given to sustainability features. Pros and cons of starting with a DfE-exemplary product Let’s explore the pros and cons of packing numerous DfE attributes into one or two products, while incorporating minimal DfE features in the rest of the product line. (These pros and cons are summarized in Table 2.) The main “pros” are to expose executives, designers, and customers to DfE principles such that over time business-savvy DfE features will spread into entire product lines. Marketing and Sales learn to position environmentally-advantageous products to the most receptive markets and emphasize the lower cost of ownership and environmental benefits. The company likely will experience positive publicity about the one product, which carries over into customers’ desire to do more business with the company overall—spurring sales of the products not yet packed with DfE attributes. Stakeholder loyalty will increase: Employees feel pride in their company, investors view this as a plus, and environmental organizations may publically praise the accomplishment. A precedent will be established for a sustainability-minded business model, as well, which can be applied to other products. My favorite advantage of this strategy is that once a design engineer achieves technology, performance, and market wins based on DfE principles, he or she will likely be drawn to incorporate more and more sleek DfE elements into every product designed thereafter. The main “con” is the possibility of drawing attention to customers and other stakeholders the fact that your company’s other products are not as environmentally responsible. A TFI client in the insurance industry points to a potential issue with “eco” products that stand alone in a company’s product line, because this practice could make them vulnerable to a claim about a standard product’s health or environmental hazard when the company has demonstrated sufficient knowledge to design and manufacture an environmentally responsible one. Another disadvantage is that the market (or a non-government organization) could view the singular product as a move to capture positive attention, without doing the work to transform the entire product line to DfE (the expression “red herring” comes to mind). Finally, executives may permit this one DfE-exemplary product to be designed and sold without developing broad-based strategies for requiring DfE principles in all designs – with phase gates and internal audits; in other words, the singular DfE product could lack the momentum to bring about others. It’s much more efficient, of course, to convince executives of the business benefits of wide-spread DfE requirements and not to take it too slowly by focusing on only one product to start.

Table 2. Summary of Pros and Cons to Releasing a Single DfE-Exemplary Product

Resistance to the idea and how to overcome it We’ve not run into much resistance at client companies regarding DfE training; once the executives understand the business and competitive benefits they are usually amenable to funding DfE workshops. And following the training DfE elements start popping up in product designs everywhere. But we have run into resistance about packing a singular product with as many DfE features as possible. “It could cost more,” some say. “We’ll have to market it differently,” say others. Change is not always welcome. Here are some ways to overcome these reservations: • Find out if a competitor has released such a product, and make this fact known. • Analyze key customers’ latest Request for Quotes (RFQs), and point out the numerous DfE requirements • See if there are influential designers who will lobby strongly for approval of an innovative, efficient design. • Finally, give your designers an experience of designing a DfE-exemplary product. How can your designers experience designing a DfE-exemplary product? About a year ago we added another hands-on exercise to our DfE workshops. We form teams comprising the client’s designers (best if at least one electrical, mechanical, and manufacturing/test engineer is in each team) and challenge each one to design a practical yet visionary product within their company’s mission. The team incorporating the most DfE principles in a feasible and marketable design wins. We’ve found that it’s a competitive - and fun – way to build your team and give them a direct experience of designing DfE products. Attendees have reported back to us that it’s an “eye-opening” practice and forever changes how they approach product design. Designing a DfE exemplary product can clearly bring significant benefits to your company, including positive publicity, shifting awareness and emphasis to total cost of ownership, increased customer and stakeholder loyalty, and increasing your designers’ knowledge and motivation to design DfE products. At the same time, it’s not for everyone. We recommend carefully considering your product design strategies – knowing that whether you focus on a DfE exemplary product or disseminate DfE throughout your product designs (or both!), your company and customers will only benefit. About the Author Ms. Gordon is founder and president of Technology Forecasters Inc. (TFI), a strategic consulting firm serving some of the world's best known electronics companies in best-practice supply chain and profitable environmental steps. In 2001 she wrote the book Lean and Green: Profit for Your Workplace and the Environment, published by Berrett Koehler Publishers. |

|

網內資料 : |

|

Loading |

|