|

|

|

PRO/ENGINEER

2003年第二季軟體技術文件

2003/04/01

Be Flexible in Wildfire

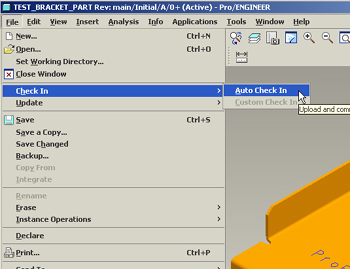

Flexible Components is a new function in Pro/ENGINEER Wildfire that gives users

added capabilities for assembly management. The Make Flexible command allows

users to change solid objects into flexible objects existing in different states

inside an assembly. Each occurrence of the component can have a different

flexibility assigned to it, and it will only show up as one BOM item. Having

this capability eliminates the need for multiple unique object numbers for a

single object displayed in different states. Prior to Wildfire, it was necessary

to create unique objects or family tables when attempting to display the same

spring in different states of compression in the same assembly. This added extra

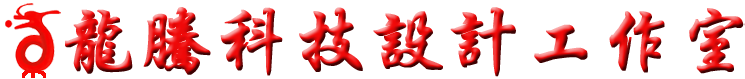

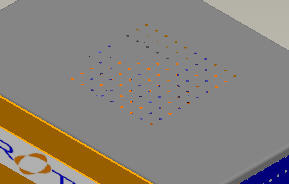

items to the BOM and required a manual change to correct. Figure 1 shows

five uncompressed springs assembled to holes in a circular housing. The four

springs around the outer surface of the housing are sitting on washers that are

located in the middle of each hole.

Figure 1

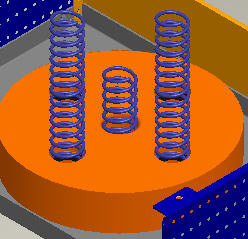

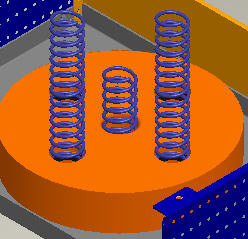

The center spring is located in a hole that has no washer, so it rests on the

surface of the chassis to which the housing is assembled. When the cover of the

chassis is installed, the four springs will protrude through the top of the

cover while the fifth spring (fully uncompressed) just touches the inside of the

top cover. (See Figure 2.)

Figure 2

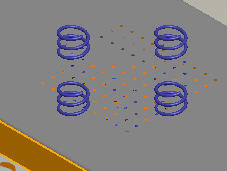

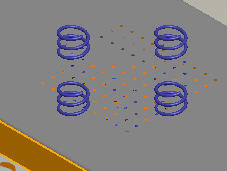

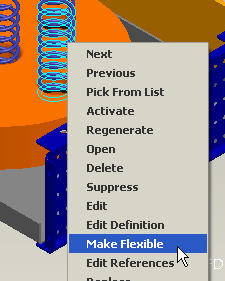

Compressing the four springs that are assembled to the outer holes on the

housing so that they just touch the inside of the top cover, can be accomplished

in Wildfire by making the springs "Flexible" components. Highlight one of the

springs that you wish to compress and click your right-mouse button. Select

Make Flexible from the pop-up menu. (See Figure 3.)

Figure 3

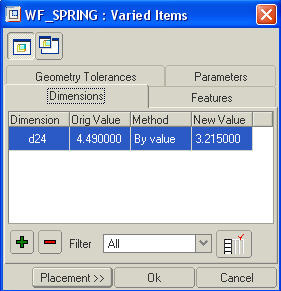

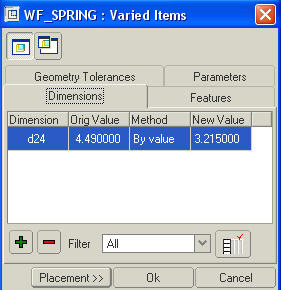

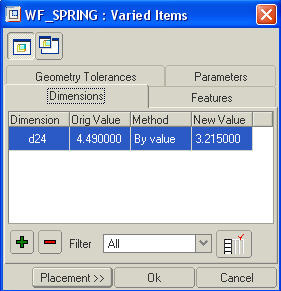

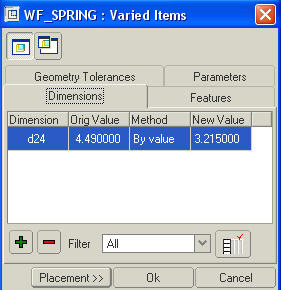

The Varied Items dialog box will appear. (See Figure 4.)

Figure 4

Select the green add button and use the Search Tool to find the

dimension in the spring that will allow it to be compressed. Select Apply

and select OK from the Select box. The dimension you selected will be

visible in the Varied Items box. (See Figure 5.)

Figure 5

Change New Value to allow the spring to just touch the inside of the top

cover and select Placement from the Varied Items dialog box. The

Component Placement dialog box will appear with a new button called Define

Flexibility. This button allows you to go back and modify the flexibility values

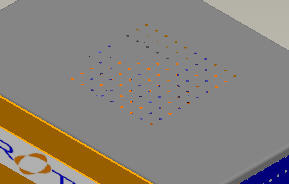

(varied items) of the spring. Select OK from the Component Placement

dialog box to complete the operation. The springs should be completely inside

the top cover, as shown in Figure 6.

Figure 6

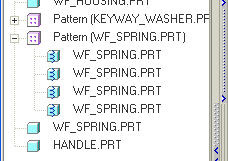

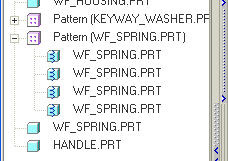

Inside the model tree, the four springs will have a new icon attached to them

indicating that they are flexible components. (See Figure 7.)

Figure 7

--Submitted by Stan Balish, president and chief executive officer, FroTime

Inc., San Diego, CA

How to Flatten a Harness Without the Network

(This tip can be applied in Wildfire in the Harness-MFG module.)

In previous releases, harness networks were flattened automatically with the

wires, cables or bundles in a flattened harness. The only way to remove the

network was to blank on a layer.

In Pro/ENGINEER Wildfire, the config.pro option "fan_with_network" has been

added and may be set to NO (default is YES) to exclude the network

from being flattened.

--Submitted by Florin Neamtu, principal engineer, PTC technical support,

Needham, MA

Determine What Materials to Use

When parts are in the early development stages, it is not always clear which

material to use. For example, 50 percent long glass polypropylene has a

different performance characteristic and density than 20 percent short glass.

Rather than modifying the Pro/ENGINEER part's density every time you want to

look at its total weight, you can write a relation to maintain as many options

as you wish. See below:

weight_material_1 = density * mp_volume("")

weight_material_2 = density * mp_volume("")

Substitute the material name and density values as needed. The "weight_material_*"

parameter then can be displayed as a parametric note on a drawing or used for

further calculations.

--Submitted by Steven J. Frey, vice president, Universal Parametrics, Inc.,

Ann Arbor, MI

Show a Mechanism Position on a Drawing

Under Drag Dialog, snapshot the mechanism position. Use the

make-available-in-drawing icon to make the snapshot visible in the drawing.

Create a new view or modify an existing view. Set the type as exploded. The

mechanism snapshots will be listed as an exploded state.

--Submitted by Ian Turner, design application support, CSC, MBDA UK Account,

Stevenage, UK

Drawing Snap Lines

Use snap lines to expedite drawing cleaning. A snap line is a line that shows up

on the screen but not on the printed drawing. It allows you to line up balloons,

notes or any draft entities that can be moved using the normal move command.

When an entity is selected and moved near the snap line, it snaps to it.

The moved entity will change colors when it is attached to the snap line. By

using the snap line, balloons can be lined up perfectly straight. The figure

below shows several balloons lined up on two snap lines.

Snap lines can be defined on individual drawings to locate dimensions, notes,

geometric tolerances, symbols and surface finishes. The system positions the

snap lines relative to the view outline, a selected model edge or datum plane.

After you place an item on a snap line, the item moves if the grid line moves

(such as when the view outline expands).

When placing and locating items on snap lines, keep the following two points in

mind:

- When you move an item onto one snap line, its color changes to magenta. If

you set the location by pressing the left-mouse button, the item snaps to the

snap line. Until you move the item again, the snap line determines its

location.

- If you move an item onto the intersection of two snap lines, the system

highlights one of the lines in red. If it snaps that item to more than one set

of snap lines at that location, you can navigate all possible sets using the

SEL SNAP LINE menu. When you choose Accept, the system locates the item on the

intersection of the two snap lines. When you move either snap line, the item

moves with it.

To Create a Snap Line:

- Select Insert >Snap Line on the menu bar.

- On the Menu Manager, do one of the following:

| Choose CR SN LINE >Att View. Select a view border and

specify the offset from the border and the number of lines to create. If you

are creating more than one line, specify the space between the two lines. The

snap line attaches to the specified view border. |

| Choose CR SN LINE >Att Geom/Snap. Select view geometry (such as an

edge), a datum plane or another snap line. Specify values for the offset, the

number of lines to create and the space between the two lines (if you are

creating more than one line). The snap lines attach to the specified view

geometry, datum plane or snap line. |

You can snap an item to one snap line or to the intersection of two snap

lines. You can also attach clipped detail entities such as dimensions, witness

line endpoints, set datum endpoints and axis endpoints.

You can place the following items on snap lines:

| Dimensions |

| Clipped dimension arrows |

| Notes |

| Symbols |

| Set datum names |

| Set datum line endpoints |

| Geometric tolerances |

| Surface finishes |

| View arrows |

| Balloons |

--Submitted by Sayeeprasad G., engineering assistant, Miller Fluid Heads,

Artarmon, Australia

Automating Pro/E, Pro/INTRALINK Installation

Here is a not-so-well-documented technique that enables you to:

| Automate your Pro/E and Pro/INTRALINK installation. |

| Use PTC.Setup trail files. |

| Record every click and entry you make in the setup program and

automatically replay the steps for each new Pro/E installation. |

This will save a lot of time and prevent you from having to be at the

computer to make the right picks. Here are the details:

| Run your setup with the option -uilog on the command line: ptcsetup -uilog.

|

| Perform all the selections needed for a standard installation including

license servers, installation folder, etc. |

| The trail file ps_trl.txt.numeric suffix is created in the current folder.

Rename the trail file (for example, setup.txt) and place it in a convenient

place such as the bin folder. |

| Write a script to call setup within the trail file and place it in the

same folder: ptcsetup -uitrail setup.txt |

There also is the option of running setup without displaying on screen (use -nographics

option): ptcsetup -nographics -uitrail setup.txt.

See the PTC description in TPI 103331 for more information.

This technique is especially useful for installing Pro/INTRALINK. You could

incorporate it into your standard installation procedure so all new clients are

set up with the correct paths, servers, etc.

--Submitted by Edwin Muirhead, CAD systems administrator, Aberdeen, Scotland,

UK and

www.geocities.com/proehelp/index.html?admin.htm#setup

Response Pro/Clues 3 - Vol. 2, Issue 3

I would still have to be at the computer to log into it as an administrator and

to start the process. A user does not have rights to install most programs. How

can I get around this?

--Stephen Galayda, CAD system administrator assistant, HydraForce, Inc.,

Lincolnshire, IL

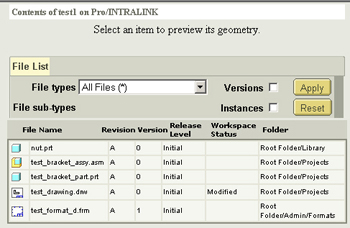

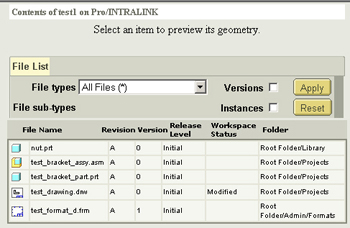

Sizing Pro/INTRALINK Columns

To get your Pro/INTRALINK columns to be only as big as needed, point your mouse

over the column heading and hit the right-mouse button. They will adjust

automatically, usually narrowing to the longest entry listed.

--Submitted by Sandy Buerkle, designer, Welch Allyn Inc., Skaneateles Falls,

NY

Response PRO/CLUES 4 - Vol. 2, Issue 3

In addition to resizing one column with a right-click:

| Hold down shift and right-click. This resizes the column and columns to

the right. This is useful for resizing all columns in the window. |

| Left-click to sort by column. |

| Hold down shift and left-click to add a second sort column. |

--Ed Muirhead, CAD systems administrator, Aberdeen, Scotland, UK.

2003/04/18

Q1- Vol. III, Issue 13

I am trying to model the shin guards (shown below) in Pro/ENGINEER, but I am

having trouble getting the shape to be correct. Can you recommend any advanced

tutorials or other training guides to help me solve this modeling problem?

--Andrew Walter, engineering student, Australian National University,

Canberra, ACT Australia

A1.1- Vol. III, Issue 13

The profile of the skin guard you show on the picture seems quite complex. It is

better to first digitize it using a laser digitizer or CMM. Afterward, bring the

digitized data into Pro/E.

--Yasir Arfeen, CAD/CAM engineer, OJ Pvt. Ltd., Karachi, Pakistan

A1.2- Vol. III, Issue 13

The best tutorials at student rates can be found at

www.frotime.com.

--G. Alexander Korentis, mechanical/biomedical engineer, QCI Engineering,

University of Connecticut, biomedical engineering doctoral student, Storrs, CT

A1.3- Vol. III, Issue 13

Take the "Advanced Surfacing Training" course offered by PTC or Rand.

--Chris Boyer, manager of product creation, Freudenberg Household Products

LP, Northlake, IL

A1.4- Vol. III, Issue 13

You might try looking into medical archives. If an FTP site exists for your

software, you may find proven applications there.

--Craig D. Skogerson, Indio, CA

Q2- Vol. III, Issue 13

I just received Pro/ENGINEER Wildfire and I am concerned about its stability. In

the past, I have heard it was wise to wait a few months before installing new

versions. Has anyone had problems with Wildfire and would you recommend I wait

until any possible bugs are worked out?

--Pascal Normand, designer, research and development, Industrial Handling

Division, IPL Inc., St-Damien, Quebec, Canada

A2.1- Vol. III, Issue 13

I've been using Wildfire for about a month and I have not come across any bugs

yet. I do stress yet. I have found it much better and easier to use than

R2001 once you get to know where everything is. An important addition is the

Menu Mapper under the Help menu. To find out how to do something in Wildfire,

open the Menu Mapper. The Menu Mapper shows an R2001 screen with the old-style

menu layout. After you run through the R2001 way of executing the command, using

the R2001 menus shown, the Menu Mapper will show you how to do it in Wildfire.

It is an excellent tool.

--Jeff Taylor, mechanical production engineer, Imagination Technologies Ltd.,

London, UK

A2.2- Vol. III, Issue 13

I installed Wildfire and just did my first real rush job with it. I took nine

hours nonstop and a large thermos of coffee. But I got it done. This was the

first time I used it. I have had no training on it. That speaks to its usability

and the fact that the interface has not changed a lot from the previous version.

However, Wildfire crashed four times doing routine tasks. Thankfully, no

critical steps were lost, and I was able to carry on. But it is definitely not

yet stable.

--Christopher J. Purcell, defense research and development, Canada Atlantic,

Dartmouth NS, Canada

A2.3- Vol. III, Issue 13

Wildfire does not work with Pro/INTRALINK.

--Tom Hargrove, fusion energy division, Oak Ridge National Laboratory, Oak

Ridge, TN

A2.4- Vol. III, Issue 13

You are right. Often it is better to wait for some builds after the first

production edition of a new Pro/E release. I have not tried Wildfire yet, but

I'll wait at least a couple of months before using it in a production

environment.

--Luca Armellin, mechanical engineer, Metelli SpA, Brescia, Italy

More Answers to Previous Questions

Q1- Vol. III, Issue 12

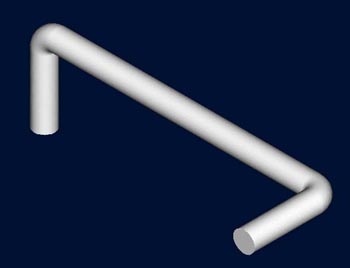

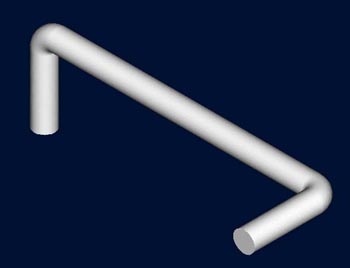

I have modeled a rod with two bends on two different planes. How do I unbend the

rod shown in the image below?

--Herb Spaulding, product engineer, Miller Industries, Ooltewah, TN

A1.1- Vol. III, Issue 12

Create a datum curve that follows the path you want. If it is a 2D path you want

to follow, you have to use the 2 Projections option in the Curve menu. Select

Insert >Datum >Curve and choose 2 Projections. If you choose two

datums at right angles to each other, they will create a datum curve where the

two intersect. You can then create a sweep. Select Create >Protrusion >Sweep

and choose Select Traj. Select the datum curve you have just selected and

sketch a round section. This technique can also be used to create sweeped pipes

in assemblies.

--Brian Middlemore, CAD support engineer, NCR Ltd., Dundee, Tayside, Scotland

Bar

Datum curve

A1.2- Vol. III, Issue 12

If you have modeled the rod with a toroidal bend tweak and you want to obtain a

straight workpiece, suppress the toroidal features.

--Zachary Popov, mechanical engineer, Technical University, Varna, Bulgaria

Q2- Vol. III, Issue 12

As of Pro/WILDFIRE, the internal datum plane, aka "on-the-fly" created datum

plane, functionality is removed. I am wondering if this will impair model

building?

--Alexander Fabre, B. Sc. M. E., Avalon Technology Stockholm AB, Sweden

A2.1- Vol. III, Issue 12

This functionality resides within the feature creation. While creating the

feature, click on the pause button at the bottom right of the screen. (It is

next to the preview button.) Create the necessary axes, planes, points etc, and

click on the pause button to continue building the feature. (Planes, axes,

points, etc. on the "fly").

--Roman Panov, MCAD application specialist, Engineering Data Resources AS,

Norway

A2.2- Vol. III, Issue 12

The "Make Datum" command is not necessarily removed, it has been restructured.

An "on-the-fly" datum still can be created by means of the same menu option for

creating a datum. The difference in Wildfire is that the "on-the-fly" datum

plane is an actual feature in the Model Tree and can be selected for reference

when creating other features. So "on-the-fly" datums are now more useful. The

only impairment is that users accustomed to the old menu selection have to learn

Wildfire's dashboard-style menu structure, which is easy to learn.

--Wes Gerber, mechanical design engineer, ITT Industries,

Aerospace/Communications Division, Fort Wayne, IN

A2.3- Vol. III, Issue 12

The internal datum plane functionality is not removed. It is accessed

differently. If you wish to create a datum on the fly, use the same icons or

menu picks as you would when creating "visible" datums. Datums created during

feature creation are listed in the model tree, but are automatically hidden and

grouped with the feature being created. In most cases the feature you are

creating - such as an extruded protrusion - will grab the plane you create and

use it for the sketching plane. If Wildfire does not select the created plane

automatically, then you can select it yourself. The important thing to note is

that on-the-fly datums are still with us.

--Kellie Wheatcroft, mechanical engineer, Smart Design, Perth, Western

Australia

Q1- Vol. III, Issue 12

I have modeled a rod with two bends on two different planes. How do I unbend the

rod shown in the image below?

--Herb Spaulding, product engineer, Miller Industries, Ooltewah, TN

A1.1- Vol. III, Issue 12

The model should be recreated with a straight rod and a datum curve defining the

shape you want the rod to become and then by using spinal bend. Another option

would be to create a sheet metal component of which an edge defines the

centerline of the rod. Create a datum curve that is a composite of the edge

defining the centerline. Create a solid swept protrusion that follows the curve.

Make the sheet metal component small enough to be buried within the rod. Then

flat-pattern the sheet metal portion to get your straight rod and suppress to

get the bent rod.

--Brian S. Lynn, design drafter/CAD administrator, Weil-McLain, Heating

America!, Indiana

A1.2- Vol. III, Issue 12

One way to handle this situation is to create the feature as a datum curve

instead of as a solid feature. You can create the path using two datum curves,

making sure to make a composite curve afterward. Create an extruded solid the

same length as your curves. (See Spinal Before image below.) Create a

spinal bend by selecting Feature >Create >Tweak >Spinal Bend. Work your

way through the menus and select the extrude material to bend around the

composite curve. When asked to select a plane to define the volume of bend,

select the opposing end of your extrusion to get the desired result. (See

Spinal After image below.) You can create an instance by removing the spinal

bend feature giving you both a "bent" and "unbent" form of your part. You can

also find an example of this by searching the help files using "spinal" as the

keyword.

--Greg Daniel N.D.G.A. systems analyst/MCAD administrator, SPACEHAB, Inc. /

Johnson Engineering, Webster, TX

Spinal Before

Spinal After

A1.3- Vol. III, Issue 12

Redefine your trajectory.

--Doug Rogers, project engineer - Fuel Metering Valves, Precision Engine

Controls Corp., San Diego, CA

A1.4- Vol. III, Issue 12

If the feature was not created by a trajectory protrusion, create a family table

that includes the bent feature. The new instance should have this feature set to

No. Include a feature that includes the dimension for the length and

modify that number to the correct length when the part is unbent. If it was

created by a trajectory protrusion, remodel it or these instructions will not

work.

--Karen Thacker, design engineer, Physitron Inc., Huntsville, AL

Q2- Vol. III, Issue 12

As of Pro/WILDFIRE, the "internal datum plane," aka "on the fly created datum

plane," functionality is removed. I am wondering if this will impair model

building?

--Alexander Fabre, B. Sc. M. E., Avalon Technology Stockholm AB, Sweden

A2.1- Vol. III, Issue 12

I called tech support about this question. They said to just use the Create

Datum Icon from the toolbar. It will still be a "datum on the fly". The

"Make Datum" menu pick is just not available anymore.

--Greg Morris, associate designer, The Halex Co., Bedford Heights, OH

A2.2- Vol. III, Issue 12

In Wildfire, you can still create datums "on the fly," but when you are finished

creating the feature you will have a group in your model tree that contains the

feature and the hidden datum planes. You can unhide these datums later and use

them for references for other features if you wish.

--Paul Bock, mechanical engineer, Plesh Industries, Inc., Buffalo, NY

A2.3- Vol. III, Issue 12

Based on a recent PTC webcast, the "Datum-on-the-fly" was removed from Wildfire

on the assumption that this functionality was mainly used for pattern features-a

feature that has been and will continue to be improved with Wildfire.

--Wade Williams, CAD designer, Alfmeier Corp., Greenville, SC

A2.4- Vol. III, Issue 12

The datum "on the fly" method has been removed, but it has been replaced by the

ability to create datum features within a command. Once the command has been

completed, the feature and the new datum are autogrouped and placed in the model

tree. The icon in the model tree looks similar to a copied feature icon.

--Jeff Taylor, mechanical production engineer, Imagination Technologies Ltd.,

London

Q1- Vol. III, Issue 11

How do I get the measure command to default to "by plane"?

--Bernard Henry, tooling and equipment design engineering, Knowles

Electronics, LLC, Elgin, IL

A1.1- Vol. III, Issue 11

I created a mapkey to default to "by plane." It is listed below.

mapkey meas_xyz @MAPKEY_NAMEmeasure_using_xyz;@MAPKEY_LABELmeasure_xyz;\

mapkey(continued) ~ Activate `main_dlg_cur` `ProCmdDToolsMeasure.view`;\

mapkey(continued) ~ Open `measure` `MsrTypeOptions`;~ Close `measure` `MsrTypeOptions`;\

mapkey(continued) ~ Select `measure` `MsrTypeOptions`1 `Distance`;\

mapkey(continued) ~ Open `measure` `DistToOptions`;~ Close `measure` `DistToOptions`;\

mapkey(continued) ~ Select `measure` `DistToOptions`1 `Plane`;\

mapkey(continued) ~ Open `measure` `DistFromOptions`;~ Close `measure` `DistFromOptions`;\

mapkey(continued) ~ Select `measure` `DistFromOptions`1 `Plane`;

Or you can use this one, which I believe is a standard Pro/E config.

mapkey mp #INFO;#MEASURE;#DISTANCE;#FROM PLANE;

--Arnold Collett, senior mechanical designer, Paragon Technology, Inc.,

Huntsville, AL

A1.2- Vol. III, Issue 11

I do not know if you can change the default, but you can create a mapkey using

the following sequence:

Analysis.....Measure...... Pick Distance as the type, then pick the

to and from parameters (in that order) and set them to Plane.

Stop the mapkey sequence and save it to the appropriate config.pro. By entering

a mapkey, you are instantly ready to pick your planes for measuring.

--Richard Cruz, mechanical engineer, Key Technology, Walla Walla, WA

A1.3- Vol. III, Issue 11

I find it most convenient to place an icon in my tool bar linked to a mapkey. I

have one for plane-to-plane, plane-to-axis and axis-to-axis. I measure distances

so often that I find this a real timesaver. One click and you are there.

--Dave Miller, design engineer, Commodore Machine Co., Bloomfield, NY

Thanks to our readers, we received more than two dozen answers to this

question. To read all of the answers to Q1- Vol. III, Issue 11,

click here.

Q2- Vol. III, Issue 11

Is there a way to override dimension text in my drawing, such as a linear

dimension in which I want to "lie" to state a different number? I know this is

kind of a funny question, but it is available in AutoCAD.

--Peter Zeiss. design engineer/project manager, Transparent Container - Tool

Design & Mfg. Berkeley, Berkeley, IL

A2.1- Vol. III, Issue 11

Yes there is. Replace {0:@D} with {0:@o}. It will only work if you add text

({0:@D}54, for example). This only works for dimensions created in the drawing

and not for feature-driven dims.

--Thierry Declerck, industrial design engineer, Philips Industrial Activities

NV, Philips Sound Solutions, Belgium

A2.2- Vol. III, Issue 11

Yes, there is, but it needs to be accomplished with a created dimension. Create

the dimension in the drawing, highlight it, go to Properties (the

symbolic display will be @D for the dimension). Change @D to @O (the letter O).

Any text you enter after the "O" will appear in place of the dimensional value

with the leader lines and dimension arrows.

--Mike Brattoli, senior product design technician, Moen Inc., North Olmsted,

OH

A2.3- Vol. III, Issue 11

Although I strongly recommend against doing this, it is possible. Edit the

dimension text and put an O in place of the D and type the desired text

immediately following the O. We restrict our users from doing this without

consulting an administrator to prevent problems down the road in manufacturing

and inspecting the parts or assemblies.

--Brian J. Hart, mechanical engineer/Pro/E administrator, Lockheed Martin

NE&SS-Archbald, Archbald, PA

Q1- Vol. III, Issue 8

PTC announced it might provide a config.pro option in Wildfire that would allow

users to continue to use the Ctrl key and the mouse buttons as done in prior

releases. Has anyone been able to determine if this is true, and if so, have you

implemented it and used it successfully?

--Mike Brattoli, senior product design technician, Moen Inc., North Olmsted,

OH

A1.1- Vol. III, Issue 8

I sincerely hope PTC will give Wildfire users the option of reverting to

previous zoom/pan/spin control. In a previous Pro/E Digital Digest, a

reader suggested buying a five-button mouse (four-button + scroll-wheel button)

and binding one of the new buttons to CTRL. A truly brilliant idea!

Try before you buy a five-button mouse. I found it better to have the two

additional buttons under my thumb. The symmetrical mouse, with a button on each

side, made it difficult to avoid activating the fifth mouse button while holding

in the thumb button and one of the standard three buttons while dragging.

It takes a day or two to get used to it, but I would never go back. I have

total control with the mouse and it makes the new controls requiring Shift, Ctrl

and differing Pan control between 2D and 3D seem like a giant leap backwards.

--Patrick Morris, product designer/mechanical engineer, Allied Telesyn

Research, Christchurch, New Zealand

A1.2- Vol. III, Issue 8

There is no config.pro option available, but you can use the spaceball to act as

your mouse. I found the spaceball is more useful than the mouse and ctrl button/

Here is the link to spaceball. www.3dconnection.com

--Raymond Yung, mechanical engineer, Arista Networks, Palo Alto, CA

Q1- Vol. III, Issue 10

If I have completed a U-shaped round tube using the sweep function, how can I

create the centerline in the drawing?

--Derek Soon, assistant engineer, design, vehicle construction department,

DelGro Engineer Pte Ltd.

A1- Vol. III, Issue 10

Make a datum curve. Select the curve as trajectory when you make the sweep. On

the drawing, change the line to a centerline. You have to use Hidden line

in the drawing view to see the centerline.

--Johannes Noval, mechanical engineer, Denmark

Q1- Vol. III, Issue 9

What kind of Pro/E experience or training is required to become a Pro/E

administrator?

--John Kopacki

A1- Vol. III, Issue 9

You need to take the following training courses:

| Introduction to Pro/ENGINEER (five days) |

| Fundamentals of Design (five days) |

| Pro/ENGINEER System Administration (three days) |

| Pro/INTRALINK Administration (five days) |

--Jay Sussman, president, Torgon Industries, San Diego, CA

2003/04/21

Q1- Vol. III, Issue 15

I am trying to find a way to get information turned into parameters from

Pro/MANUFACTURING. Do you know how to convert mfg_feat.inf file results "cutting

time:" and "z_min:" into a parameter that can be used in Pro/RERPORT?

--Patrick Kimlin, owner, NK Designs Inc., Ann Arbor, MI

A1- Vol. III, Issue 15

I never managed to do this. Instead I exported the manufacturing information to

a text file and edited it so that it contained only the relevant and applicable

information. This included cutting time, speed, feed, tool, etc. Then I put it

on the drawing in the form of a note.

--Steven Hatch, production design engineer, Global Marine Systems Ltd.,

Chelmsford, England

Q2- Vol. III, Issue 15

How can I update Pro/E Wildfire (code 2002490) from Pro/E 2001 (code 2001440)?

--Nguyen Thai Duong, Victory, Hanoi, Vietnam

A2- Vol. III, Issue 15

A user wanting to upgrade to Pro/E Wildfire has two choices:

- Load Wildfire, but leave release 2001 on your computer.

- Uninstall release 2001 and install Wildfire.

In either case, the CD will walk you through the installation process. The

only real choices that need to be made involve how the licensing is handled on

your computer (locked license vs. floating licenses) and whether you should load

Help files.

--Mike Brattoli, senior product design technician, Moen Inc., North Olmsted,

Ohio

Q1- Vol. III, Issue 10

If I have completed a U-shaped round tube using the sweep function, how can I

create the centerline in the drawing?

--Derek Soon, assistant engineer, design, vehicle construction department,

DelGro Engineer Pte Ltd.

A1- Vol. III, Issue 10

Create a curve through the center plane of the U-shaped tube following its

trajectory. Change the linetype properties of the curve to a centerline.

--Tony Havern, design engineer, Moffett Engineering Ltd., Dundalk Co., Louth,

Ireland

A2- Vol. III, Issue 10

In your model select Create Datum Axis >Through Cylinder. Select the

swept extrusion. The axis will be placed at the center of your extrusion and can

be used in the drawing.

--Terry Hendrick, tool designer, Means Industries, Inc., One Way Clutch

Business Unit, Saginaw, MI

A3- Vol. III, Issue 10

If you create it as a hollow pipe, the centerline will show by default.

--Simon Lewis, mechanical design, Control Techniques, Wales, UK

A4- Vol. III, Issue 10

In the model, sketch a curve and modify its line style and color. Use that curve

as the trajectory to create the swept protrusion. If the curves are displayed on

the drawing, the centerline will show automatically.

--Jason Shuey, tool designer, Anchor Packaging, Paragould, AR

A5- Vol. III, Issue 10

Use a sketched datum curve to create the sweep path. Use the curve to create the

sweep. Modify the curve's line style to be centerline style. Make your drawing

and create a section view of the part to see the curve.

--Ryan W. Rush, application engineer, EDS TSG/Engineering Systems, Rochester,

NY

A6- Vol. III, Issue 10

Unfortunately, this is not an option in Pro/E but there is a work-around. To

dimension the centerline of a bent tube, create a datum curve for the trajectory

of the swept feature. Instead of sketching the trajectory in the feature

creation, create a datum curve as the trajectory. To do this, click on Select

Traj and click the datum curve instead of choosing Sketch Traj. This is

easily dimensioned in the drawing.

--Luke Andrew, design engineer, Dutro Co., Logan, UT

A7- Vol. III, Issue 10

I had the same problem creating center points for radius centers on drawings.

The only way I was able to do it was by creating a cosmetic sketch in the part

model parametrically aligned to the radii centers. The same thing can be

accomplished to create a cosmetic sketched line for the centerline.

--Kevin Sullivan, product engineer, Nice Ball Bearings, Kulpsville, PA

A8- Vol. III, Issue 10

Create a datum curve and use it to create the sweep (select sweep). In the

drawing, show hidden lines and modify the line to centerline.

--Dave Fischer, senior designer, Hobart Food Equipment Group, Troy, OH

A9- Vol. III, Issue 10

Create a cosmetic feature that references the datum curve that was used for the

sweep feature. Create a cosmetic sketch and select Use edge, picking the

datum curve as the edge to use. Change the appearance of the cosmetic to be a

centerline by picking Geom Tools and Cosm Font. Select the sketch

edges and change the style using the dialog box that pops up. Any changes to the

curve will follow with the cosmetic. If you add or delete a segment of the

original datum curve, you will have to fix the cosmetic manually. If you need to

control the location of the cosmetic, set it to a unique layer and set that

layer for a particular drawing view only.

--Bill Jensen, senior product designer, Dana Traction Technologies

A10- Vol. III, Issue 10

If you swept the U-shaped protrusion along a previously constructed curve, using

it as the center point of your U-shaped sketch, you may show the curve in your

drawing. You can hit Use Edge of the curve, relate it to the view and

place the curve on a layer and turn it off. Change properties of the curve to

"centerline". The sketched entity should behave in the drawing as though it were

a part of the solid geometry.

--Deron M. Drach, Whirlpool

A11- Vol. III, Issue 10

Set the line style of the driving curve to be centerline and, in the drawing (in

display mode/edge display), set that entity to be 'wireframe' in the views in

which you want to see it.

--John Wade, Wade Org., UK

A12- Vol. III, Issue 10

The best solution would be to work inversely. Create a datum curve and run the

sweep along the curve. The curve's font can be changed later to centerline font.

If the swept feature exists already, you may create a composite curve along the

edge of the surface of the feature. If it is a tube with a circular section, the

surface will be split and you can use the surface-edge option. After the

composite curve is completed, you can create an offset curve from it at the

correct distance. Be sure to connect the distance with the tube diameter using

correct relations.

--Uriel Avron, chief executive officer, Harmonic Systems (UA) Ltd., Israel

2003/04/23

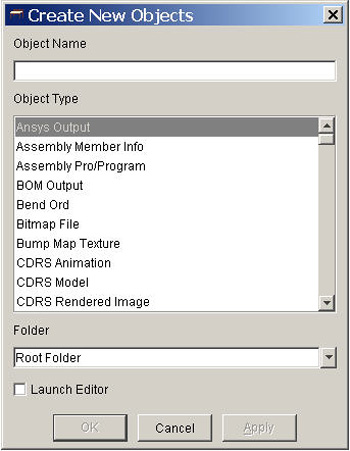

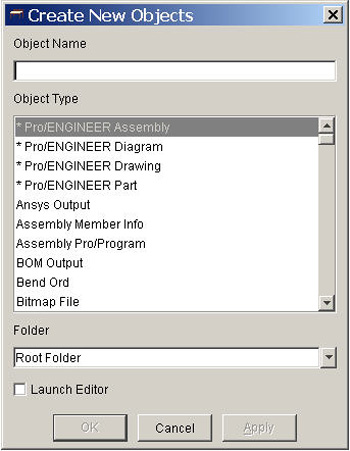

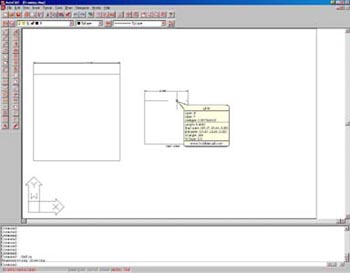

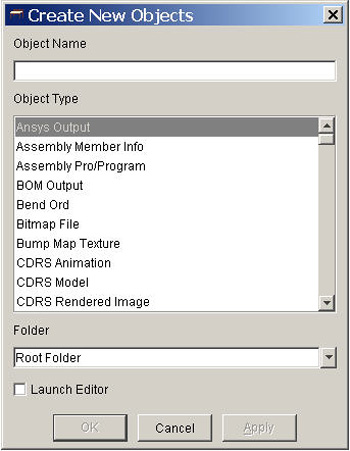

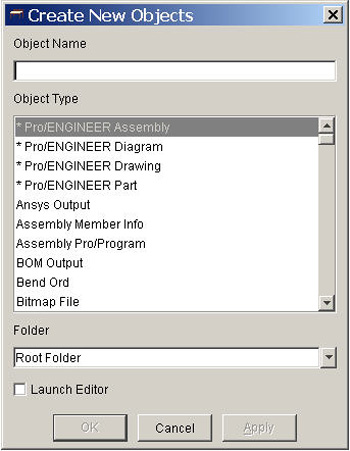

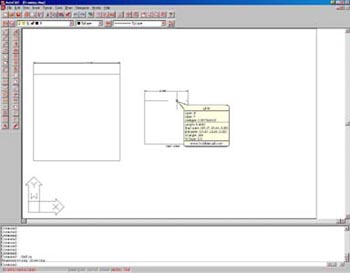

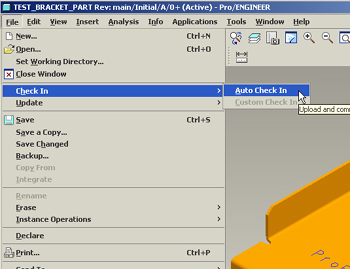

Customizing the Object New Menu in Pro/INTRALINK

Pro/INTRALINK has the capability to create new objects in your workspace. This

method involves using the selection Object >New from within the Workspace

browser. The problem is that to use this method, you must scroll through many

object types before coming across the Pro/ENGINEER object types. (See Figure

1.) This can be frustrating, but there is a way to solve the problem.

Figure 1

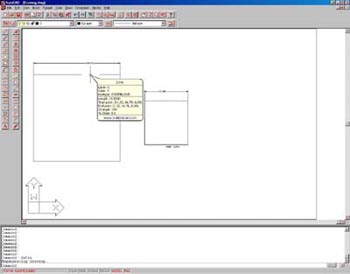

If you have administrator privileges within Pro/INTRALINK, you can send the

Pro/ENGINEER object types to the top of this list. Open the administration

portion of Pro/INTRALINK by selecting Administration from the main Pro/INTRALINK

menu or Intralink >Administration from within either the Commonspace or

Workspace browser. Once inside the administration portion of Pro/INTRALINK,

expand the Object category to view the available options. Select the Object

Types category to view all the defined object types in the database. The

system will sort according to the object type description field. To easily find

the Pro/ENGINEER object types, sort the Description column. Scroll to

find the descriptions that begin with Pro/ENGINEER.

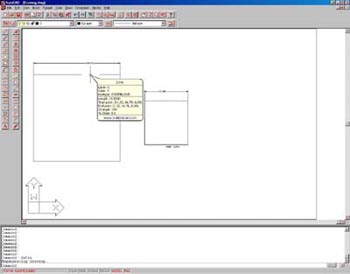

There are a few ways to get the object types to appear at the top of the list.

Place a symbol or number in front of the description name. (See Figure 2.)

Figure 2

There are only a few Pro/ENGINEER types you need to put at the top of the

list. These are:

| Pro/ENGINEER Assembly |

| Pro/ENGINEER Drawing |

| Pro/ENGINEER Part |

Using this technique, you can sort other object types commonly used within

your environment. To see what the Object New dialog looks like after the

change, select it from within the Workspace browser. The object types should

appear at the top of the list. (See Figure 3.)

Figure 3

--Submitted by Eric Horn, FroTime Inc., San Diego, CA

Creating a Four-Sided Box With Flanges on Top

This tip covers a fast way to create a standard four-sided box with flanges on

top. Typically, a Pro/E user would start the part in Pro/SHEETMETAL and create

each wall and flange separately. To save time, start the part in Pro/SOLIDS and

convert the part to Pro/SHEETMETAL. This cuts in half the amount of features it

takes to create the box or part. This is important when working with large

assemblies because it avoids lengthy regeneration times.

| Go to File >New Part >Subtype >Solid. |

| Create your solid protrusion with sharp corners. |

| Make a cut in the top of the box to create an opening. In making the cut

size, take into account the size of the flanges you require for the top of the

box. The depth of the cut would be blind. Set the depth to the thickness of

the material such as .125, .250 or .187. |

| Shell out the box by using Feature >Create >Shell. Select the

inside of the box as the material to remove. Select a thickness equal to the

number you selected for material thickness when you created your cut on the

top of the box. This guarantees uniform thickness. |

| Select Application >Sheetmetal and select a driving surface. Choose

the default thickness. The box is now a Pro/SHEETMETAL part. |

| Select Feature >Create Conversion. Select your point reliefs, edge

rip and rip connect. |

With this method, it takes only five features to create a four-sided box with

flanges on top.

--Submitted by Charles Niemotka, Tobyhanna Army Depot Pro User Group,

Tobyhanna Army Depot, Tobyhanna, PA

Automating Pro/E, Pro/INTRALINK Installation

Here is a not-so-well-documented technique that enables you to:

| Automate your Pro/E and Pro/INTRALINK installation. |

| Use PTC.Setup trail files. |

| Record every click and entry you make in the setup program and

automatically replay the steps for each new Pro/E installation. |

This will save a lot of time and prevent you from having to be at the

computer to make the right picks. Here are the details:

| Run your setup with the option -uilog on the command line: ptcsetup -uilog.

|

| Perform all the selections needed for a standard installation including

license servers, installation folder, etc. |

| The trail file ps_trl.txt.numeric suffix is created in the current folder.

Rename the trail file (for example, setup.txt) and place it in a convenient

place such as the bin folder. |

| Write a script to call setup within the trail file and place it in the

same folder: ptcsetup -uitrail setup.txt. |

There also is the option of running setup without displaying on screen (use -nographics

option): ptcsetup -nographics -uitrail setup.txt.

See the PTC description in TPI 103331 for more information.

This technique is especially useful for installing Pro/INTRALINK. You could

incorporate it into your standard installation procedure so all new clients are

set up with the correct paths, servers, etc.

--Submitted by Edwin Muirhead, CAD systems administrator, Aberdeen, Scotland,

UK and

www.geocities.com/proehelp/index.html?admin.htm#setup

Sizing Pro/INTRALINK Columns

To get your Pro/INTRALINK columns to be only as big as needed, point your mouse

over the column heading and hit the right-mouse button. They will adjust

automatically, usually narrowing to the longest entry listed.

--Submitted by Sandy Buerkle, designer, Welch Allyn Inc., Skaneateles Falls,

NY

Recreating Assemblies in Pro/MECHANISM Design

Although it is possible to convert existing assemblies into Pro/MECHANISM,

experience shows it is easier to recreate an assembly. One reason is that

components often are assembled in a different order than what is required within

Pro/MECHANISM.

Avoid conflicts between joint-axis settings and drivers. If joint-axis

settings and drivers conflict, the assembly may fail when running the motion. In

most cases, the failure is caused by the driving trying to push a component

beyond its joint-axis limits.

--Submitted by Ian Turner, design application support, CSC , MBDA UK Account,

Stevenage, UK

2003/04/28

Q1- Vol. III, Issue 16

Is there a way to cross-hatch (Xhatch) a section in which the hatching is

something other than lines? I would like to have circles or other shapes

repeated in my cross-hatching.

--Dan Bailey, product development engineer, Emerson Appliance Motors, St.

Louis, MO

A1.1- Vol. III, Issue 16

I can provide a partial answer to your question. To generate cross-hatching

other than the default "slanted lines", do the following in Pro/E 2000i^2:

| Pick Modify >Xhatching and select the cross-hatching you wish to

change. |

| In the MOD XHATCH menu, pick Retrieve. A selection of different

cross-hatch files (corresponding to different materials) will be available. In

the case of 2000i^2, the choices are rather limited (aluminum, copper,

electric, glass, iron, plastic, steel, titanium and zinc), and are just other

simple line patterns. These cross-sections are .xch files and are located in

the ":\ptc\Proe200i2\text\crosshatch" directory. |

The portion of your question left unanswered is where to find, or how to

generate other varieties of cross-hatch patterns to store in this or another

working directory. Perhaps others can answer this part or provide a better

solution.

--Richard Cruz, mechanical engineer, project engineering, Key Technology,

Inc., Walla Walla, WA

Q2- Vol. III, Issue 16

I just received Pro/E2001 and I am trying to create dimensions. It does not work

when I place my new dimensions in Sketcher or on the print itself. Is there a

special setting that I need to know about?

--Sue Coupal, drafter II, Eaton Corp., Selma, NC

A2.1- Vol. III, Issue 16

Your question is somewhat confusing. If you create a drawing and choose View

>Show and Erase, a window will open that gives you the option to pick

different types of dimensioning schemes. This function uses the dimensions that

you use in Sketcher when creating geometry.

--Garry Enyart, Fort Recovery Industries

2003/05/02

Q1- Vol. III, Issue 17

How do you organize Pro/ENGINEER files? In other words, which EDM/PDM system do

you use?

--Dirk Scherer, PROCAD GmbH & Co. KG , Projektleiter, Germany

A1.1- Vol. III, Issue 17

We use MatrixOne as our PDM solution. The MXPRO integration adds a pull-down

menu directly in Pro/E and is easy to use for file management and vaulting.

--Emmanuel Stathopoulos, senior mechanical engineer, Hyperchip Inc.

A1.2- Vol. III, Issue 17

We use Product Center from STI/WTC.

--Brian S. Lynn, CAD administrator/design drafter, Weil-McLain, Michigan

City, IN

Q1- Vol. III, Issue 16

Is there a way to cross-hatch (Xhatch) a section in which the hatching is

something other than lines? I would like to have circles or other shapes

repeated in my cross-hatching.

--Dan Bailey, product development engineer, Emerson Appliance Motors, St.

Louis, MO

A2- Vol. III, Issue 16

I do not know how to add circles as part of the pattern. You can however create

additional cross sections. Go to MOD XHATCH and retrieve one of the existing

patterns. You can add/delete lines as well as modify the font and weight. When

you finish, select Save, type the name of the pattern and hit Enter.

The pattern will be saved in your working directory. After saving it, you can

move it to the crosshatching directory. If you want to keep your custom patterns

separate from the defaults, create a new folder and add the following line to

your configuration file: pro_crosshatch_dir path. You can also assign crosshatch

patterns automatically to a cross section. In your part, assign a material by

selecting Set Up >Material >Define or Assign. (We utilize a

material library). Name your crosshatch files to correspond with the material

names. If the system finds a pattern with the same name as the material (without

the .xch extension), it automatically assigns it to the cross-hatch section.

--Randy Hagen, sustaining engineer, VIASYS Healthcare, Palm Springs, CA

2003/05/09

Q1- Vol. III, Issue 18

Can anyone explain to me why curves created between two points using the "thru

points" option are not accepted as trajectory during sweep feature creation? How

can I get around this?

--Manohar Dapakara, Eicher Motors Ltd., Indore, India

A1.1- Vol. III, Issue 18

These curves will be accepted if you use the single-radius or multiple-radius

options. Splines, which are the default curve types for thru points, cannot be

used as trajectories for a sweep.

--Thomas G. S. Peterek, Active Design Consulting Inc., Kitchener, Ontario,

Canada

A1.2- Vol. III, Issue 18

Assuming you are using Wildfire, use the variable section sweep.

--Niloy Guha, product executive-mechanical design automation, Rolta India

Ltd., Calcutta

A1.3- Vol. III, Issue 18

You can overcome this problem by using variable section sweep or swept blend.

--Ravi Kiran, application engineer, CSM Software Ltd., Banglore

A1.4- Vol. III, Issue 18

When curves between two points are created, often the end points of those curves

are unable to be perpendicular to the curve trajectory. There are two ways to

overcome this problem. After selecting the curve use the trim/extend command and

extend the endpoints for a specified distance. This allows for endpoint

alignment to a sketch plane because the extension is straight. The drawback to

this method is that only a single loop can be used for the sweep.

A second method is creating either a 2projection curve for complex

three-dimensional trajectories or a sketched curves. In Sketcher, select the

points you would like to go through as you sketch references for placement. You

will need a straight section for your start point, so the sketch plane can be

created perpendicular to the trajectory. These two-curve creation methods are

more powerful in that they will accept multiple-loop sketches and are less

likely to fail.

--Lee Hughes, Pro/E designer II, Kohler Co.

A1.5- Vol. III, Issue 18

When you create datum curve thru points and use them for sweep, Pro/E is not

able to find adjacent reference surfaces to determine the surface to which your

section will be normal. Use advanced option, selecting Feature >Create

>Protrusion >Advanced >Swept Blend. After selecting the datum curve as the

trajectory, Pro/E will ask you for a surface to which your section will be

normal. Show it that surface and you will accomplish your task.

--Yogesh Gaikwad, executive-product design and engineering, Fleetguard

Filters Pvt Ltd., Pune

A1.6- Vol. III, Issue 18

The reason you could not select the two-points curve as your sweep trajectory is

that you did not sufficiently define the orientation of the curve. Go back and

redefine the former two-points curve with its orientations and you will be able

to create your sweep with a two-points curve.

--Yang Xue Liang, senior project engineer, Xuzhou Meritor Axle Co. Ltd.

Q2- Vol. III, Issue 18

How can I set the attribute Name as the default instead of Branch

in the Locate Common Space Objects window of Pro/INTRALINK? I am using version

3.0 of Pro/INTERLINK.

--Sameeulla Baig, designer, Zamil Aircon, Dammam, Saudi Arabia

A2.1- Vol. III, Issue 18

Usually your administrator is the only one who can set this option but if you

have administrative rights, here is what you would do. Select Intralink

from the pull-down menu and click on Administration. Select Object

>Attributes >Object Attributes. Create an attribute called "Name" if there

is not already an attribute with that name. Select the pull-down menu and click

on Name and enter the value.

--Jeff Macon, engineering team member, eServ LLC, Rock Island, IL

A2.2- Vol. III, Issue 18

Set up your own locate folder. Here is how to set your computer to locate the

latest revision: (clock symbol) & version (clock symbol) along with the name

(=). To set up your own locate menu, pick Name (=) and select the

plus button on right. This should put it under Attribute >Operator.

Select Create and name your setup for Locate. Pick this file,

double-click in the value column and proceed as normal.

--Denise Hartranft, designer, Auburn Clutch Division

New Answers to Previous Questions

Q1- Vol. III, Issue 17

How do you organize Pro/ENGINEER files? In other words, which EDM/PDM system do

you use?

--Dirk Scherer, PROCAD GmbH & Co. KG , Projektleiter, Germany

A1.1- Vol. III, Issue 17

I use PTC's Pro/INTRALINK.

--Andy Singletary, engineering systems technology manager, Bristol

Compressors, Inc., VA

A1.2- Vol. III, Issue 17

We use the Windows NT Server, letting it handle security and permissions. This

is accomplished by creating subfolders. One folder is for users to work within,

one folder is for the Library data, one folder is for Pro/E and company

standards, one folder is for the release process and one folder is for the

released "golden" file. Everyone has read privileges to these folders, but

depending on their role in the engineering department, users may or may not

determine the folders to which they can write. To protect the files, we move

them from folder to folder. In Windows NT, we have to copy the files from folder

to folder and delete files to allow the file to gain the security permissions of

the folder. We have written programs using Excel and Visual Basic to assist in

moving files from folder to folder. The system works well, especially if you

have no money for PDM. It also mimics the way Pro/INTRALINK works to a certain

extent. Users have a workspace, the golden file folder is like common space and

the release process folder is similar to the promotion scheme. One problem is

the quality of the data. So to ensure data quality, we maintain the history of

prior released data in a Zip file. By renaming the Pro/E number on the end of

the file, we ensure that data is not lost. Another problem is duplicate data.

This system lends itself to using the backup-file command in Pro/E, so most of

our user directories are mini libraries. It has taken about a year to work out

the bugs and get everyone on board. We are trying to implement Pro/INTRALINK 3.2

at this time with the main goal being electronic signature. So far we have the

database running and configured and are beginning to import data.

--Doug Meyhoefer, principle mechanical engineer, L-3 Communications Display

Systems, Alpharetta, GA

A1.3- Vol. III, Issue 17

We use MatrixOne as our PDM solution. The MXPRO integration adds a pull-down

menu directly in Pro/E and is easy to use for file management and vaulting.

--Emmanuel Stathopoulos, senior mechanical engineer, Hyperchip Inc.,

Montreal, Canada

Q2- Vol. III, Issue 16

I just received ProE2001 and I am trying to create dimensions. It does not work

when I place my new dimensions in Sketcher or on the print itself. Is there a

special setting that I need to know about?

--Sue Coupal, drafter II, Eaton Corp., Selma, NC

A2- Vol. III, Issue 16

Select Insert >Dimension > New References and make your choice. There are

no sketched dimensions.

--Alejandro Arzate Silva, mold design engineer, Applica Manufacturing,

Querétaro, México

2003/05/15

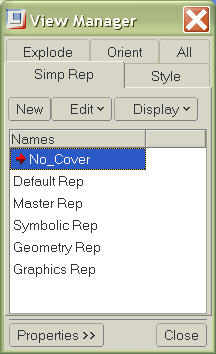

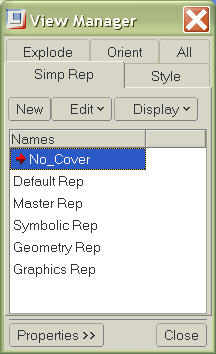

View Manager in Pro/E Wildfire

The new release of Pro/E Wildfire has introduced many new user interface (UI)

components and as a result has shifted some commonly used functions. One of the

new UI components is the View Manager, which brings together previously separate

components into a single dialog box. The components that were in version 2001 of

Pro/E included:

| Simplified representations |

| Explode states |

| Model orientation |

| Component display |

(See Figure 1.)

Figure 1

With the new View Manager, some of these components have new names.

Simplified Reps is Simp Rep. Model orientation is Orient. Explode

states is Explode, and Component display is called Style. The

names have changed, but the same functionality remains within the View Manager.

The way to get to these components, however, has changed.

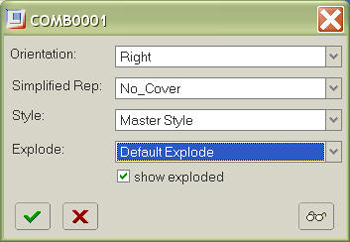

To learn the changes, experiment with the available options. One of the most

confusing is creating and defining a new simplified rep, explode, orient or

style. To do this, choose the New option and give it a new name. While it

is still highlighted, select the Edit >Redefine option. This will allow

you to define the new view state. When you create a new view state, Pro/E will

not have you define that state automatically. You must redefine it.

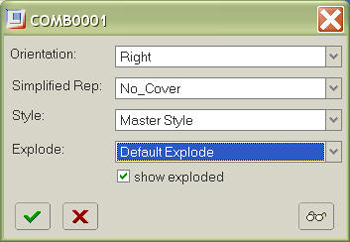

The View Manager allows you to define view states that include all four view

components. You can select from each of the following: Orientation, Simplified

Rep, Style and Explode. You also can choose either to explode or not explode the

view by using a check box. The check box is available because there is no

"unexploded" option in the pull-down menu. (See Figure 2.)

Figure 2

--Submitted by Eric Horn, vice president of research and development,

FroTime Inc., San Diego, CA

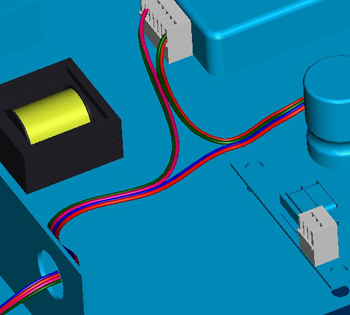

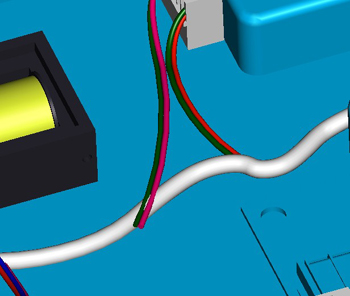

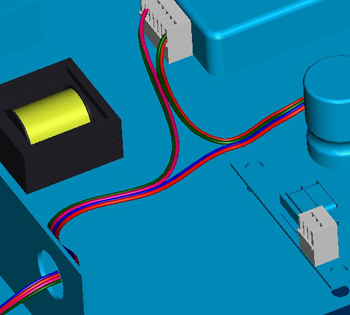

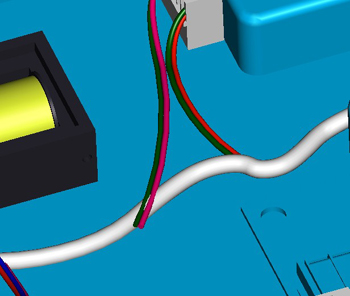

Creating a T Junction in Pro/CABLING

This technique will show how to create bundles using Pro/CABLING that form a

T-shaped junction. Consider the situation shown in Figure 1, where wires

form a three-sided branch.

Figure 1

In Release 2001 and later, "branch" bundles can be created to represent

T-junctions of wires and cables.

Select Feature >Create >Bundle, and enter a name for the bundle.

Select the type of grouping and whether or not it has a sheath. Use Along

Path and select the beginning and end locations of the horizontal segment of

the "T." Pro/ENGINEER will prompt, "Do you want to include partially routed

cables on the path?" Select Yes and use Sel All and Done Sel

to select all the wires to include in the bundle. Accept the default parameters

or enter new ones. A bundle will be created that encompasses the wires that run

along the horizontal portion of the "T." Figure 2 shows the result.

Figure 2

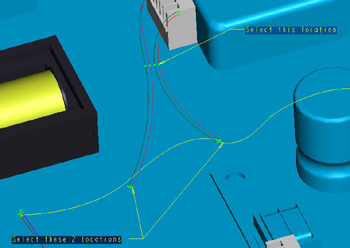

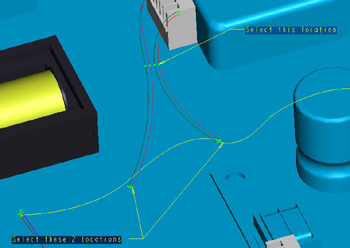

To create the vertical section of the junction, create another bundle and

select Branch from the BUNDLE OPTS menu. Pro/ENGINEER will prompt,

"Select one or two locations on a top loom bundle to define one end of the

branch." Select the two locations on the horizontal bundle where the wires of

the vertical portion of the "T" intersect it, and choose Done Sel.

Pro/ENGINEER will prompt, "Select a location to define the other end of the

branch." Select the location on the vertical wires where the bundle will begin.

(See Figure 3.)

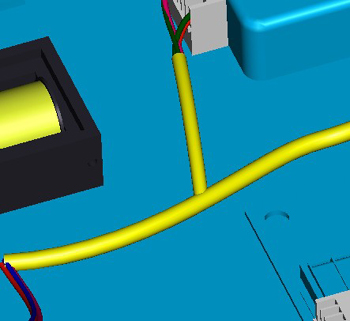

Figure 3

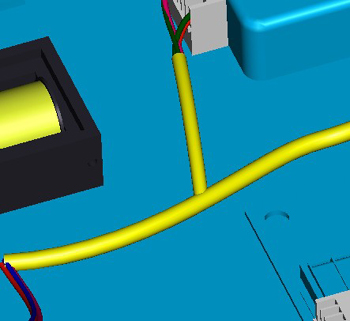

Pro/ENGINEER will create the second bundle. When finished, the bundles will

intersect in a T-shaped junction. (See Figure 4.)

Figure 4

--Submitted by Florin Neamtu, principal engineer, PTC technical support,

Needham, MA

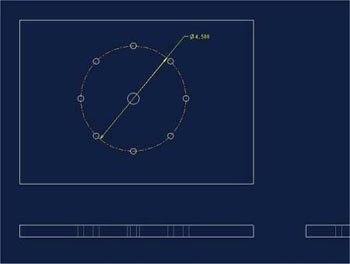

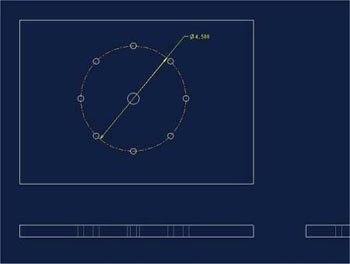

How to Show Bolt Circle Diameter on a Drawing

Frequently designers need to show the diameter of a circular bolt hole pattern

on a drawing. Doing this is much simpler than one would expect.

An option exists in the drawing.dtl file that is turned off by default. To

show the bolt circle diameter or radius (whichever you used for the pattern), go

to the Menu Manager and choose Advanced >Drawing Setup in 2001 or File

>Properties >Drawing Options in Wildfire.

From within the Drawing dialog box locate "radial_pattern_axis_circle," and

set the value to Yes. Choose View >Show and Erase from the

pull-down menus and show axis on the view to which you wish to display the bolt

hole circle. (See Figure 1.)

Figure 1

--Submitted by Thomas G. S. Peterek, Active Design Consulting Inc.,

Kitchener, Ontario, Canada. With thanks to Andrew Burke and Gabriel Martinez.

Showing Various Mechanism Positions Without MDX

In the "Drag Dialog", snapshot the mechanism position, use the "Make Available

in Drawing" icon to make the snapshot visible in the drawing. Set and snapshot

the mechanism at all the positions you wish to communicate. Make all available

to the drawing. A user without Mechanism Design can view the various mechanism

states by using the Explode State menu, with the use set at current to pick one

of the mechanism snapshots.

--Submitted by Ian Turner, design application support, CSC, MBDA UK Account,

Stevenage, UK

Ref. Dimensions in Drawing Mode

Sometimes users receive an error message saying, "Highlighted dimensions cannot

be regenerated." (See Figure 1.) When a Reference Dimension misses its

reference edge for regeneration of the created dimension, it can become

unattached. Delete the Ref. Dim. and create a new one. But you also can Reroute

Attached Edge by selecting the Ref. Dim and using the third-mouse button. Hold

it and select Reroute Attach and choose the new references.

Figure 1

--Submitted by Palle Srinivasa Reddy, senior engineer—CAD, GE India Business

Centre, Begunpet, Hyderabad, India

2003/05/16

Q1- Vol. III, Issue 19

In Pro/E 2000i, what is the best software to create graphical presentations

using my Pro/E models? I am finding that models pixilate heavily when I export

images as .tif files and open them in PhotoShop. Does 3D Studio or another

software prevent this distortion?

--Jamal Shoukry, design engineer, Opus Fena, Buckinghamshire, UK

A1.1- Vol. III, Issue 19

I have found that the best way to export models for presentation is by using

capture software such as Capture EZE Pro by Application Techniques, Inc. You can

capture the whole screen, just the model window or a part of the window and

export to a long list of file types. I prefer .jpg files.

--Frank Johns, design engineer, Newville, PA

A1.2- Vol. III, Issue 19

I've gotten better results using a screen-capture program such as Screenprint

than I have by directly exporting images. You can save the images in a variety

of file formats including .gif and .jpg.

--Keith Hooks, mechanical engineer, HHP

A1.3- Vol. III, Issue 19

Try rendering the output file as Postscript rather than .jpg or .tif. By doing

this, you can control the image size and DPI. I used this method to generate

images for a large trade show display and the results were excellent. For those

who do not have Photoshop, the output can be viewed using GhostView. GhostView

can be downloaded for free. Visit

ftp://mirror.cs.wisc.edu/pub/mirrors/ghost/gnu/ghostview/.

--Brett Burdick, manager of product development, Fi-Shock, Inc., Knoxville,

TN

A1.4- Vol. III, Issue 19

Making a .tif file requires time for menu selection, size choices, dpi (100-600)

and image depth (8-bit index, 24-bit RGB, mono, grayscale). Also .tif files are

huge. Instead, I use the Print Screen key function, which creates an image

instantly. I paste it into documents (Word, Excel, PowerPoint) and crop it. My

screen area is 1,600 x 1,200 pixels and this setting creates fine screen dumps.

To create engineering documents (i.e., GD&T on ECN), I use SnagIt5, which can

be found at www.techsmith.com.

A windows screen capture utility offers the option of what box zone on the

screen to capture; therefore, no cropping is required. You can paste different

areas in forms without having to save extra files, or you can save a file in one

of the seven file-type options. I open CompuPic from

www.photodex.com, paste,

"print screen" capture, adjust the image and save as one of the 12 file options

for future use in graphic suites—.bmp or .psd or .jpg.

--Carrie Ellen Hall, mechanical designer III, Thetford Corp., Ann Arbor, MI

A1.5- Vol. III, Issue 19

The easiest way to render models from Pro/E is to translate them into .iges or .vrml

formats, open them into 3dsmax and then render them. See images below.

Image 1

Image 2

--Chad Waldo, design engineer, R&D Tool and Engineering, Lees Summit, MO

A1.6- Vol. III, Issue 19

Increase the dpi of the output, but remember that doing this makes the file size

larger.

--Warren Weber, engineering manager, Bucher Aerospace Corp., Everett, WA

A1.7- Vol. III, Issue 19

I typically use Snagit to get pictures of Pro/E files. The picture will be

exactly what you see on the screen and you can save it in a number of formats.

You probably can download a test version from

www.techsmith.com.

--Claes Albertson, team leader mechanical CAD, Tetra Pak Carton Ambient AB,

Lund, Sweden

A1.8- Vol. III, Issue 19

To overcome this problem, simply save (do not export) the Pro/E file as a .jpg.

Once you open the .jpg file in Photoshop, you will see it is crystal clear.

3dsmax does the job best, but results vary depending on your graphics card.

--Pratik Madhavji, CAD designer, product developer, London, UK

A1.9- Vol. III, Issue 19

We use MS PowerPoint for presentations. To keep it simple and looking good we

use screen capturing. We position the model to the desired orientation and then

select Alt/Print Screen. (It's an old Windows trick.) This takes a

snapshot of your active window. If you want the full screen, use

Ctrl/Print Screen. Just paste the image into PowerPoint or the presentation

program of your choice. Once the image is in PowerPoint, you can crop, move and

resize it. It looks good and does not become pixilated. If you need a .jpg or

tif file format, use Save As and select the image format.

--Chris Novrocki, mechanical engineer, Lockheed Martin, Naval Electronics &

Surveillance Systems, Archbald, PA

A1.10- Vol. III, Issue 19

When I export Pro/E models, I export them as .jpgs at 600 dpi. When I open the

image in Photoshop, I am able downsize the image without losing detail or

causing it to pixilate.

--Matthew Fink, tech manual design, Miller Industries Towing Equipment Inc.,

Ooltewah, TN

Q2- Vol. III, Issue 19

In Wildfire when I make a sketch, the interface slows or is slow. I have

a Pentium4, 560 RAM memory and NVIDIA 32MB card. My graphics are excellent when

I spin solid features. What is the optimal requirement for Windows PCs?

--Alejandro Arzate Silva, mold design engineer, Applica Manufacturing,

Querétaro, México

A2.1- Vol. III, Issue 19

We had the same problem running PIII 800 with 512MB of RAM and a 32MB video

card. We upgraded to the NVIDIA 750XGL (128MB) graphic cards. This seemed to

solve our problem. Another thing I did was clear the computer and reinstall

everything from scratch. This seemed to help as well. Whenever my computers

start acting up and running slow, a good "Format C:" always seems to help.

--Aron J. Oler, senior drafting technician, Belden Wire & Cable - Electronics

Division, Richmond, IN

A2.2- Vol. III, Issue 19

Here is the link to the PTC website that shows the minimum and optimal

requirements for Wildfire:

www.ptc.com/partners/hardware/current/proe.htm.

--Kyle Davidson, Racar International, Anderson, IN

A2.3- Vol. III, Issue 19

Although you have a 32MB graphics card, I have heard from a couple different

tech support people that Wildfire is a graphics hog. When you are in Sketcher

you are using your graphics memory the most. A smaller card like yours will slow

it down. I have an Elsa Synergy II 32 MB graphics card and it does the same

thing on all of our machines. I heard the recommendations to run Wildfire are:

| Pentium 4 2.0 GHz processor (minimum) |

| 1.0GB RAM |

| NVIDIA Quadro4 900XGL 128MB graphic card. (On the NVIDIA website it notes

that this is a PTC-certified graphics card.) |

I am waiting for two new machines that are a step up based on the above

recommendations. They have:

| Pentium 4 2.4 GHz processor (minimum) |

| 1.5GB of RAM |

| NVIDIA Quadro4 900XGL 128MB graphics card |

We will see how much it helps.

--Sam Osier - designer, VIASYS Health Care - Critical Care Division, Palm

Springs, CA

A2.4- Vol. III, Issue 19

Change your graphics card. I had the same setup at home and the same problem

happened to me. Upgrade to at least 64 and it will be OK. But for the best

performance get a high-end graphics card such as a Wildcat. The problem does not

surface in 3D mode because 3D representatives do not use as much memory as

sketches. In sketches, you need more video memory due to accuracy settings.

--Abdul Mukmin Bin Burhan Tajuddin, product development engineer, Siemens VDO

Automotive, Malaysia

Q3- Vol. III, Issue 19

Where can I find online tutorials about Pro/E v2001 or Wildfire? I am looking

for a complete course in .pdf or .html format. Is it available on CDs and where

can I find it?

--Ramanan Selvam, tool design, LuK India Ltd., Hosur, India

A3.1- Vol. III, Issue 19

For online tutorials regarding Pro/E Wildfire, visit these sites:

www.ptc.com/community/proewf/newtools/index.htm

www.ptc.com/community/proewf/newtools/tutorials.htm

www.ptc.com/community/proewf/newtools/personal_productivity.htm

Also, there are often online courses from technical education organizations such

as universities. They are a bit harder to find, but are often free.

--Steffen Förster, MCAD application specialist, PTC, ICenter, Central Europe

A3.2- Vol. III, Issue 19

A California company called Frotime has .pdf files and models that you can

download. Some are free. Visit

www.frotime.com/home.asp.

--James Foster, contract designer, Honeywell Aerospace, South Bend, IN

A3.3- Vol. III, Issue 19

CADTRAIN offers a complete e-Learning curriculum for both 2001 and Wildfire. The

CADTRAIN content is web-based, so you can access it from any browser or you can

receive it on CD.

--Dave Cohen, vice president, CADTRAIN, Irvine, CA,

www.cadtrain.com

A3.4- Vol. III, Issue 19

I've found a brief tutorial for Pro/E Wildfire on the PTC site at

www.ptc.com/community/proewf/newtools/tutorials/1/. It is a 21MB Zip file

containing an html tutorial showing how to begin using Pro/E Wildfire in the

shortest amount of time. The tutorial assumes you are familiar with Pro/E. If

you are looking for a complete Pro/E tutorial, visit

www1.coe.neu.edu/~zeid/mim3350(spring01)/index2001.html.

--Luca Armellin, mechanical engineer, technical department director, Metelli

SpA, Cologne BS, Italy

A3.5- Vol. III, Issue 19

I've had great luck using Google to search "Pro +tutorial". Here's one link I

found:

www.caddigest.com/subjects/pro_engineer/tutorials_proe.htm

--Kevin P. Alexande, enterprise CAD/PDM consultant, Intergraph Solutions

Group, Cincinnati, OH

New Answers to Previous Questions

Q1- Vol. III, Issue 18

Can anyone explain to me why curves created between two points using the "thru

points" option are not accepted as trajectory during sweep feature creation? How

can I get around this?

--Manohar Dapakara, Eicher Motors Ltd., Indore, India

A1.1- Vol. III, Issue 18

You will have to use the swept blend feature under the advanced protrusion

option if the two points are not in the same plane. This is true even though the

cross-section of the protrusion is constant.

--Kevin Sullivan, product engineer, Nice Ball Bearings, Kulpsville, PA

A1.2- Vol. III, Issue 18

If you want use the curves that were created between two points using the Thru

Points option, you must define the attributes of the curve.

--Grand Fan, mechanical engineer, Casio Electronics Design Center (G.Z.) Co.,

Ltd., China

Q2- Vol. III, Issue 18

How can I set the attribute Name as the default instead of Branch

in the Locate Common Space Objects window of Pro/INTRALINK? I am using version

3.0 of Pro/INTRALINK.

--Sameeulla Baig, designer, Zamil Aircon, Dammam, Saudi Arabia

A2- Vol. III, Issue 18

It appears that you cannot change the default attribute listed for the Locate

Commonspace Objects browser. The most you can hope for is to create a saved

search and use that every time.

--William Robinson, CAD administrator, Valleylab, Boulder, CO

Q1- Vol. III, Issue 17

How do you organize Pro/ENGINEER files? In other words, which EDM/PDM system do

you use?

--Dirk Scherer, PROCAD GmbH & Co. KG , Projektleiter, Germany

A1- Vol. III, Issue 17

We use Product Center by Workgroup Technology, Corp./Softech, Inc. We have been

using it since 1997. It works well. It is stable and well seasoned. We are using

it primarily for vaulting all CAD data. It does a good job of revision control

because it understands the parametric relationship of the Pro/E files. (We

attempted to use a directory structure for a while but that became cumbersome,

inefficient and hard to control.) We also use Product Center for AutoCAD and

CorelDraw files. It is also capable of BOM and workflow tasks. Unfortunately, we

have other systems in place for these tasks.

--Bill Pier, supervisor, drafting design, Weil-McLain, Michigan City, IN

Q2- Vol. III, Issue 16

I just received ProE2001 and I am trying to create dimensions. It does not work

when I place my new dimensions in Sketcher or on the print itself. Is there a

special setting that I need to know about?

--Sue Coupal, drafter II, Eaton Corp., Selma, NC

A2.1- Vol. III, Issue 16

I've run into this situation when setting up new workstations. Check your mouse

settings and set the properties on the middle button to Middle Button.

This will enable placing dimensions in Sketcher and drawing modes. If the middle

button is not set properly, dimensions cannot be created in Sketcher or Drawing

modes.

--Rich Miller, designer, Siemens Energy & Automation, Inc., Spring House, PA

A2.3- Vol. III, Issue 16

Your question is somewhat confusing, but if you create a drawing and then choose

View > Show > Erase, a window will open that gives you the option to pick

different types of dimensioning schemes. This function uses the dimensions that

you used in Sketcher when creating your geometry.

--Garry Enyart, designer/CNC programmer, Fort Recovery Industries, Inc., Fort

Recovery, OH

2003/05/24

Q1- Vol. III, Issue 20

I was disappointed to find nothing written about Standard Triangulation Language

(STL) files in the article "Interoperability Creates Capability" by Tom Kopinski,

which ran on Page 12 in the March/April issue of Pro/E: The Magazine. My

experience is that this is a neutral file format that never causes problems

because it is a simple mathematical representation of a model. The .stl file

format handles the geometry as a skin of mating triangles that are only

represented by three coordinates (x,y,z). This file format is useful with rapid

prototyping machines and high-speed milling machines. I can export this file

format from Pro/E, but I'd also like to produce cutter location files based on

my .stl model. I can import them into Pro/MANUFACTURING, but the possibilities

end there. I cannot place a coordinate system and I cannot select the surface.

How does Pro/E handle this problem? Did I do I something wrong or is it

impossible to do this? This is important because in the future I think tool and

die makers will want to work with the .stl format.

--Jef Verheyen, MCAD user and teacher, De Nayer Institute, School for

Engineers

To read the Pro/E: The Magazine article in full or receive other

valuable Pro/E information, subscribe to Pro/E: The Magazine at

www.proe.com/orderonline.htm.

A1- Vol. III, Issue 20

STL files work great for rapid prototyping when each layer is a few thousand

surfaces thick. Smooth curves are not really possible in the process, anyway.

The fundamental issue is that it forms curved surfaces with a plethora of

triangles. You cannot choose a surface because it is not one surface—it is up to

thousands of possible surfaces. A way to reach an approximation is to use more

triangles, which can increase file size dramatically. That is one area where an

IGES or STEP conversion is superior.

--Al Irion, mechanical engineer, Chipless Metals, Mequon, WI

Q2- Vol. III, Issue 20

How can I edit the default light? It is impossible to sketch a new feature in

shaded mode without hanging the light. Using a mapkey seems to be the only

workaround, but I would like to solve this problem once and for all by editing

the default light.

--Pascal Leroux, industrial design technologist, INO, Sainte-Foy, Quebec,

Canada

A2- Vol. III, Issue 20

You have to use a mapkey. There is no other workaround unless Wildfire has

something to offer that I do not know about.

--William Robinson, CAD AdminValleylab, Boulder, CO

Q3- Vol. III, Issue 20

Does PTC have a deep-draw, metal-stamping simulation module available for Pro/E

Wildfire?

--Ross H. Liberty, owner, Factory Pipe, Ukiah, CA

A3- Vol. III, Issue 20

They have a die module. I design dies. PTC came to our office to do a

demonstration. The module was nice for simple progressive and bending dies. If

you are looking for software that helps develop the blank size or helps to show

where the material could crack, look into second-party software. Check out a

company called Automated Analysis Corp.

--Jason Pavloff, design engineer, Cosmos Manufacturing, South Chicago

Heights, IL

New Answers to Previous Questions

Q1- Vol. III, Issue 19

In Pro/E 2000i, what is the best software to create graphical presentations

using my Pro/E models? I am finding that models pixilate heavily when I export

images as .tif files and open them in Photoshop. Does 3D Studio or another

software prevent this distortion?

--Jamal Shoukry, design engineer, Opus Fena, Buckinghamshire, UK

A1.1- Vol. III, Issue 19

Re-sampling by 200 percent in Photoshop can help overcome some edge pixilation (jaggies)

of a screengrab. TIFF exports from Pro/E offer a higher resolution than do

screengrabs. But by selecting Save As and choosing anything other than a

snapshot, you will lose customized lighting. We use Okino Nu-Graf software to

produce images of models. (See image below.) This process can interpret .slp

render files that are exported from Pro/E. It is good value as far as cost.

Finished presentations vary in quality. PowerPoint is popular and LView Pro has

a handy slideshow.

--David Robinson, Partner, London Associates Product Design, Berkhamsted, UK

A1.2- Vol. III, Issue 19