Submitted by C.R. Subramaniam, Kailasapuram Township, Tiruchi, Tamilnadu

State, India

Getting Pro/BATCH Plotting Utility to Work

This program is similar to that of AutoDesk's batch plot utility. As you will

see, it is a bit more complicated than drag and drop. The program has not been

updated since 1996. Pro/BATCH is intended to work outside of Pro/INTRALINK, so

the first few steps must be completed prior to using the software.

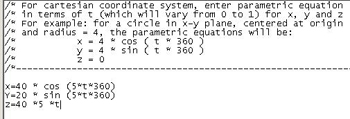

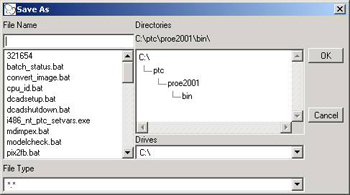

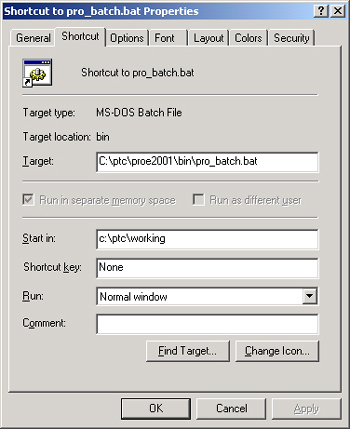

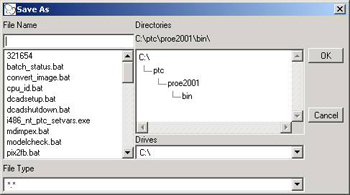

Figure 1

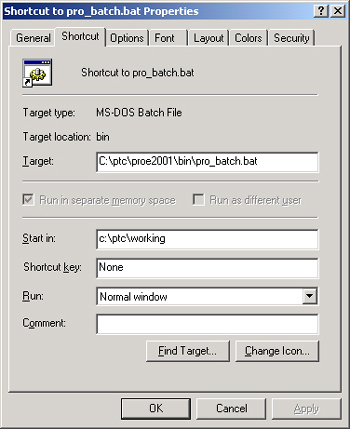

1. Create a shortcut on your desktop for Pro/BATCH found in the location

shown in Figure 1. If you do not know how to create a shortcut to this

file, do the following:

a. Open My Computer from your desktop.

b. Browse to the location of pro_batch.bat as shown in Figure 1.

c. Right-click it and select Create Shortcut.

d. Drag it out to your desktop.

2. Open the shortcut by right-clicking on it and viewing its properties.

3. Fill in the location of where your config.pro file resides, as shown in

Figure 1. You only need to complete this step once. This lets the batch file

see your config options for printing. If you fail to do this, printing will be

difficult. (You will see lots of datums, CS, thick lines, etc.)

4. Select Apply and OK.

Get the files local to your hard disk

1. Create a new directory on your hard drive. This is the location where you

will export your files. I recommend not using your working directory.

2. Check out as usual from Pro/INTRALINK into a workspace. (Drawings, models,

assemblies, etc.)

3. Open your Workspace browser window and select Edit. Select All

from the pull-down menu.

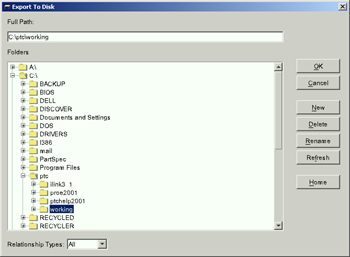

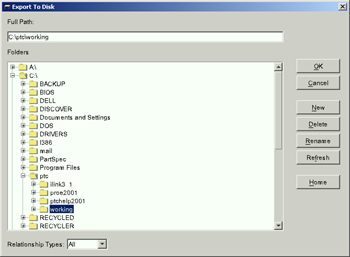

4. Select Object >Export >To Disk. (See Figure 2.)

5. Select the directory you just created to which you will export. Relationship

types should be set to All and select OK.

Figure 2

Start Pro/BATCH

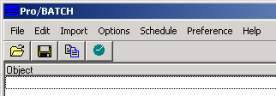

1. Launch Pro/BATCH via the new shortcut you have just created on your desktop.

Figure 3

2. Go to Preferences and set the following as shown in Figure 3. This

is the configuration that will work with our laser printer. You only can

batch-plot all the drawings in the same size. (Notice the paper-size drop down.)

The plotter command line is important: print /d:\\\.

The command line for laser printing is the following: print /d:\\lmtds\cadcam4vq.

This is different for other plotting devices. (The only space that exists in the

command is between the t in print and the /.)

Figure 4

Figure 5

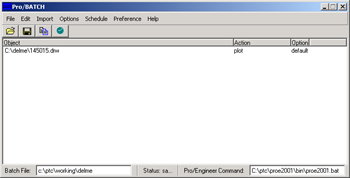

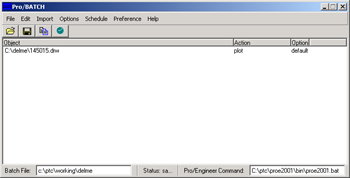

3. Next browse to the location of your exported files. You can do this by

selecting the black and blue paper-looking toolbar icon and add the files to the

list and Close. (Filter by file type if necessary-Drw, asm, prt.)

Figure 6

4. Fill in the Pro/E command: C:\ptc\proe2001\bin\proe2001.bat or wherever

Pro/E exists on your machine.

Figure 7

5. Select File Save. Name the batch file in the space provided and

save it. This can be reused if the exported files still exist locally.

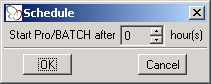

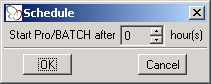

6. Under the Schedule pull down, select Start the Task.

Figure 8

7. You can tell Pro/BATCH when to send the prints by specifying 1 hr, 2 hrs,

etc. If you type 0, the prints will send immediately.

I have used this procedure only with a laser jet printer. I am unsure how it

will work with larger plotters.

2003/03/04

Scaling in Sketcher

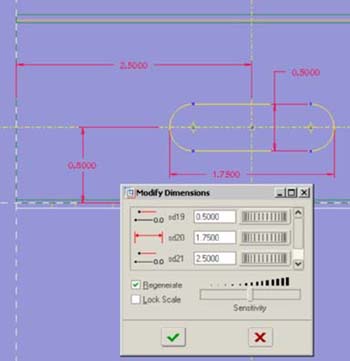

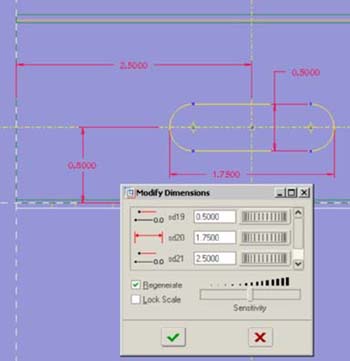

Since the introduction of Intent Manager, many users have struggled while

trying to modify dimensions inside Sketcher mode. This occurs when they fail to

take advantage of the Lock Scale functionality. With Lock Scale, managing and

controlling sketches is simplified and time spent changing one dimension at a

time is eliminated. To take advantage of this functionality, you must be inside

Sketcher mode. After you create a sketch, it is likely that the assigned Pro/E

dimensions are not what you require. (They are usually too large). Changing each

dimension, one at a time, can cause your sketch to fail, can make your sketch

confusing to look at and can be a tremendous hassle. To avoid the problem,

simultaneously highlight all the dimensions in the sketch. Do this by selecting

them singly or by dragging a box around all of them. The latter method is

quicker and more reliable. Once all the dimensions are highlighted in red,

right-click the mouse and select Modify from the pop-up menu. The Modify

Dimensions dialog box will appear. (See Figure 1.)

Figure 1

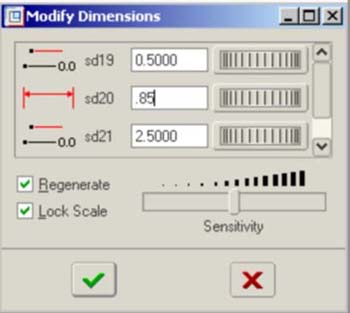

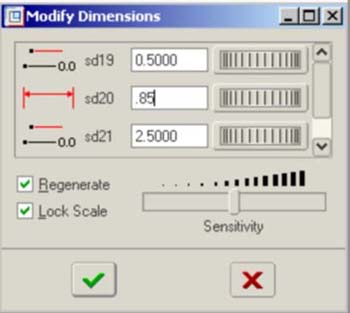

Check the Lock Scale box inside the Modify Dimensions dialog box and make a

change to the one dimension listed on the right side that you wish to change.

(See Figure 2.)

Figure 2

When you finish the dimension change and have selected the Lock Scale box,

select the red check mark inside the Modify Dimensions dialog box and the sketch

will regenerate. After regeneration, notice that the dimensions that you did not

change in the Modify Dimensions dialog box have maintained their scale in the

sketch.

--Submitted by Stan Balish, president and CEO, FroTime Inc, San Diego, CA

Selecting a Range of Features in Wildfire

A range of features or components can be selected to perform actions such as

suppress, delete, place on layer, etc. In previous releases, this was

accomplished by using the Range option in the menu. In Wildfire, this

functionality is available through the Search Tool. Launch the Search Tool by

selecting the icon or selecting Edit >Find. Select Options >Build

Query and select the History tab. Select the Number Radio Button,

and add two rules:

- Number is greater than or equal to < lower number >.

- Number is less than or equal to < upper number >.

When Find Now is selected, the desired range is found, and when

Apply is selected, the items are selected for operation.

--Submitted by Florin Neamtu, principal engineer for PTC technical support,

Needham, MA

A Lost Trick in Assembling Components

Here is how to move or spin a component that is being assembled free of the

assembly, and before it is fully constrained. Use the Control + Alt keys in

addition to the middle-mouse button (MMB) to spin it and use the right-mouse

button (RMB) to move it. This is a good way to get components into their proper

position and add constraints. It also works well if you require another

constraint and cannot determine the direction of that constraint. Once a

constraint is added, the part cannot be moved in a direction that would

contradict the constraint.

--Submitted by Kyle Davidson, Racar International, Anderson, IN, (765)

644-4727

Another Way to Create Text on Curved Surfaces

In addition to the method described in last month's Pro/Clues Digital Digest,

another way to create text on a curved surface, not only cylindrical surfaces,

is to use Offset or Draft Offset. This works well if you also need to

incorporate draft on the text.

Create a datum curve with the text. Then select Feature >Create >Tweak

>Offset or > Draft Offset. There are other options available to

control the feature, but I will not go into detail here. I will suggest,

however, that you avoid using Tangent and start with a small draft. Increase it

with Modify until you get the desired draft. The advantage to following this

method is that you can use it on any surface and it does not require outside

calculations

--Submitted by Kyle Davidson, Racar International, Anderson, IN, (765)

644-4727

Showing Various Mechanisms Positions Without MDX

In the Drag Dialog snapshot, the mechanism position uses the "make available in

drawing icon" to make the snapshot visible in the drawing. Snapshot the

mechanism at all the positions you wish to communicate and make them all

available in the drawing. A user without Mechanism design can view the various

mechanism states by using the Explode State menu. Use Set Current to pick

one of the mechanism snapshots.

--Submitted by Ian Turner, design application support, CSC Computer Sciences

Corp., MBDA UK Account, Stevenage, UK

2003/03/05

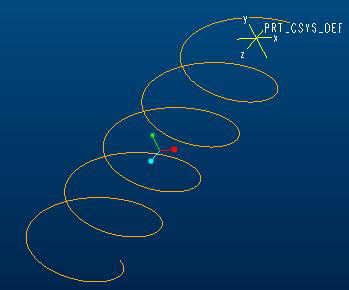

Using the Trajpar Parameter in Helical Sweep

Features

This tip is designed for Release 2001, but will work with 2000i2 as well. The

trajectory parameter, also known as trajpar, typically is used in variable

section sweep features to vary dimensions. However, the trajpar parameter also

can be used in helical sweep features to control the cross section (not

profile).

The trajpar parameter varies from 0 to 1 along the trajectory of the helical

sweep (0 at the beginning, 1 at the end).

A relation such as sd2=1+trajpar*2. (see Figure 1) would set sd2=1 at the

beginning of the sweep and 3 at the end, increasing linearly along the

trajectory. The final helical sweep would look like Figure 2.

Submitted by Florin Neamtu, senior technical support engineer for PTC

technical support, Needham, MA

Figure 1

Figure 2

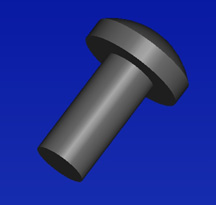

Simplify your Pro/E models

This tip is for Pro/E 2001 Build 2350. Overmodeling an object in Pro/E has a

number of disadvantages, the most damaging being unnecessary features that are

not needed to convey design intent. A common example is hardware such as screws,

nuts and fasteners. It may look cool to have your pan head cross-recess screw

modeled to exact specifications including every round and cut feature that

exists but is it necessary? These features require regeneration time. If enough

are present, the extra features may cause a decrease in your machine

performance.

If you determine that certain features of your part are not needed but might be

displayed graphically, there are a few methods you can use to accomplish this

task. One is to replace unnecessary features with datum curves. Datum curves can

be created to resemble cuts, rounds, text or protrusions that you typically

would create using normal solid features. Using the pan head screw as an

example, a fully detailed model of a pan head cross-recess screw could have

anywhere from 10 to 15 features on average. The same screw can be made with as

few as two features using datum curves to represent the cross-recess feature of

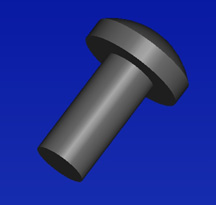

the screw. The first feature can be a simple revolved protrusion. (See Figure

1.)

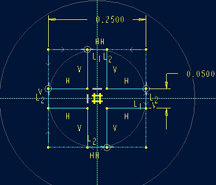

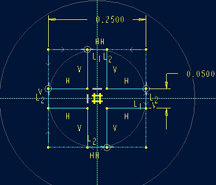

The cross-recess feature can be a projected datum curve. You can sketch the

cross-recess section on any plane or surface that is perpendicular to the axis

of the screw. Using symmetry and construction lines you can control the

cross-recess section using two dimensions. (See Figure 2.)

Select the two top surfaces that represent the top of the pan head screw.

This is where your section will be projected. Relations can then be written to

control the size of the cross-recess datum curve feature based on the head

diameter of the screw. This is useful if a family table is created for the

screw. Finally, the color of the datum curve can be set to accommodate your

specific needs using >Modify >LineStyle (this is an advantage over using

cosmetic text for the feature). The final simplified part with two features

should appear as shown below. (See Figure 3.)

Submitted by Stan Balish, president and chief executive officer, FroTime

Inc., San Diego, CA

No Online Help For Pro/MECHANICA?

PROBLEM: Have you ever been in MECHANICA Integrated Mode and tried to get

MECHANICA help through the HELP pull-down menu? If so, then you have discovered

that none of the MECHANICA manuals are listed in the Contents and Index

selection. Although you can access menu-specific MECHANICA help using the

right-mouse button on any given MECHANICA menu-pick, you cannot access the

top-level index area of MECHANICA's Help page.

EXPLANATION: When installing MECHANICA you tell it where the help

directory path is, but this is only used for the Independent Mode. With

Pro/ENGINEER Version 2001 and lower you are not able to access the MECHANICA

Help index page from within Pro/ENGINEER. Here's a method to make the MECHANICA

Help index page available while in the Integrated Mode:

PROCEDURE: Open the browser you use with your Pro/ENGINEER software.

Type the path to your Relxxhelp.htm file in the MECHANICA directory. An example

is given below for rev. 2001:

EXAMPLE PATH: D:\Program Files\promech2001\html\usascii\promec\Rel23help.htm

This is the top-level index page for MECHANICA Help. Once the page is

loaded, add it to your Favorite location (bookmark it) in the browser.

IMPLEMENTATION: To use this tip starting with a fresh Pro/ENGINEER

session, you do not have to be in the MECHANICA menu. At any time, click the

Help pull-down menu and select Contents and Index. Select the new

MECHANICA Index link in your Favorites menu after the browser comes up.

Alternatively, open your browser apart from Pro/ENGINEER and select the

MECHANICA Index link.

I do not know whether this will be necessary within Pro/ENGINEER Wildfire.

Submitted by Randy Speed, president, Speed Consulting, Waxahachie, Texas.

Speed is a member of the Pro/E Digital Digest advisory board. To read his

bio,

click here.

Solving the Problem of Showing Cosmetics on

Drawings

You have a drawing with a dozen views. There are some cosmetic features that you

have accidentally turned off in these views. You would think it would be a

simple task to use the Show/Erase dialog box and turn them back on. No such

luck. The detail item button for cosmetic features is grayed out in the show

mode. To solve this problem, turn off the preview option in the Show/Erase

dialog box. Show cosmetics does not function with preview. To turn preview off,

you must select the preview tab from the Show/Erase dialog box, make sure a

button other than cosmetic is activated, and un-check the preview box.

Gunnar B Hansen, engineer, damixa, Denmark

Avoiding Linking Problems with Archived Files

Our company has worked with Pro/E for a long time and it has archived many old

designs. Occasionally, linking problems arise when we try to retrieve the old

designs that link to other files that are archived. This can be particularly

frustrating when opening large assemblies that no longer can find files,

especially because our early system did not document what some CAD models

represented. One way to mitigate this problem is to choose the menu option to

open a simplified representation of the large assembly even if you do not know

what simplified representations exist in the model. When the list appears,

select the option to create a new simplified representation. All of the model

names in the assembly are shown without regenerating any geometry. You can

determine from the model names in the assembly whether or not it is the assembly

you are seeking, and if so you can be sure that all of the models are unarchived

before wasting time trying to regenerate the model geometry.

Submitted by Randy Palmer, mechanical design engineer, Government Systems,

Isothermal Systems Research, Clarkston, WA

More Ideas on Good Sketching Practice-Comment on

Vol. I, Issue 1, Pro Clues 2

I found Kim Cheatham's article, "Learning to sketch with Intent Manager,"

useful, but I have a couple of reservations concerning the technique. One

concern I have is the lack of attention to geometric constraints, which can

greatly reduce the number of dimensional constraints required. The method I

recommend follows:

As you sketch, points will snap to existing entities and geometric relationships

will be applied automatically according to where you move your cursor. This is

the Intent Manager making assumptions about your Design Intent. This process is

useful and you should search for the constraints. If you do not want the

constraint to be applied, move your cursor to a position to where it is not

applied and then reposition the point or entity.

Here are some steps to achieve good sketching practices:

Step 1: Use the Sketcher grid and zoom in/out to make the graphics area

the same size as your intended sketch. This will avoid problematic bit-by-bit

scaling through modification of dimensions in the sketch once it is completed.

Large movements of entities will result in extreme distortion of the sketch.

Step 2: Using Lines and Arcs (rather than trimmed circles and squares),

start from one point and create the sketch in a continuous line. Trimming

circles and squares can result in disconnected end points. This causes open

loops that are hard to fix. You also are more likely to create lines on top of

lines, which are difficult to detect. Starting from one point and switching from

line to arc as you work around the loop ensures good connections.

Step 3: Create the sketch to the correct proportions to avoid resizing

work. Drag points and entities to approximately reshape the geometry.

Step 4: Apply geometric constraints. Connect the sketch to the sketching

references and use geometric constraints before dimensional constraints to fix

its shape and proportions. This will minimize the number of dimensional

constraints. The common constraints you will use are tangency and coincidence.

Step 5: Apply dimensional constraints. It is a good practice to try to

leave the sketch with no gray, weak dimensions. This ensures all dimensions have

been considered and checked.

Step 6: Modify the dimensions. Using the pick icon, double-click a

dimension to modify it. Also, using the pick icon you can drag a box around your

dimensions to select them and then pick the modify icon to list the dimensions

for easy modification. Uncheck the regenerate option because it may cause

distortion as each dimension is updated when you make changes.

Step 7: Resolve sketch failures. If the sketch fails it is most commonly

due either to disconnection between points causing an open loop-look for weak

dimensions of zero or because you have lines on top of lines.

This last issue is the main advantage of creating the sketched loop an entity at

a time, continuing from the end point of the previous entity using line and arc

segments. This method of creating robust sketches is by no means the only way.

There are always exceptions that everyone develops in their own techniques, but

I have found this to be a good starting point. Creating robust and successful

sketches as the basis of most of the common Pro/E features is a crucial step on

the way to a successful model.

Sean Kerslake, department design and technology, Loughborough University, UK

More Help Needed on Helical Springs Clue-Comment on

Vol. I, Issue 2, Pro Clues 1

I followed the clue, "Helical Springs Around Non-Linear Trajectories" by Florin

Neamtu in the Vol I, Issue 2 edition of Pro/Clues Digitial Digest, and I

am unable to create the helical spring around non-linear trajectories. Please

advise me.

Harsha Mallikarjuna Thumbaraguddi, design engineer, Praveen CAD Systems,

Bellary, Karnataka, India

It's Not That Easy-Comment on

Vol. I, Issue 2, Pro Clues 2

Changing the setting of the new_parameter_ui option may not be as easy as

the instructions indicated. This option was not even listed under Current

Session. Once in Utilities >Options, I had to click the Find

button, type in new_parameter_ui, hit Enter and double-click on it

when it appeared in the lower window. Only then was I allowed to change the

setting from no to yes. In the process of figuring this out, I

also found the new_relation_ui option, which apparently performs a

similar function for a relations list. It also is hidden and must be changed

with the process I outlined.

Jon Smedley, senior product designer, AXXION Group, El Paso, TX

Further Questions-Comment on

Vol. I, Issue 1, Pro Clues 1

I have a further question regarding Pro/Clues 1 "File Open Dialog Features." How

do I save these settings so they are always there the next time I open a file?

If the settings cannot be saved, is it quicker to alt+tab back to my workspace

and see what I need to see?

Scott E. Szabo, manufacturing engineer, New Product Development,

Ingersoll-Rand Company, Blaw-Knox Division, Mattoon, IL

Answer to Vol. I, Issue 1, Pro Clues 1 Question

No, the settings can not be saved. In my opinion it is faster to use the file

open dialog box instead of alt+tab. But it may be faster for you.

Submitted by Stan Balish, president and chief executive officer, FroTime Inc.

in San Diego, CA

2003/04/11

Be Flexible in Wildfire

Flexible Components is a new function in Pro/ENGINEER Wildfire that gives users

added capabilities for assembly management. The Make Flexible command allows

users to change solid objects into flexible objects existing in different states

inside an assembly. Each occurrence of the component can have a different

flexibility assigned to it, and it will only show up as one BOM item. Having

this capability eliminates the need for multiple unique object numbers for a

single object displayed in different states. Prior to Wildfire, it was necessary

to create unique objects or family tables when attempting to display the same

spring in different states of compression in the same assembly. This added extra

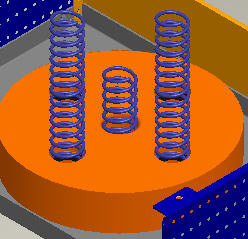

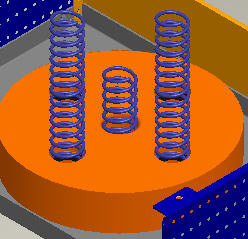

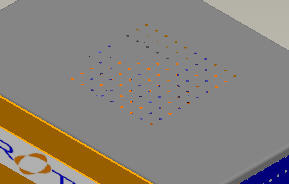

items to the BOM and required a manual change to correct. Figure 1 shows

five uncompressed springs assembled to holes in a circular housing. The four

springs around the outer surface of the housing are sitting on washers that are

located in the middle of each hole.

Figure 1

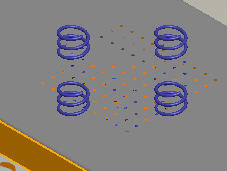

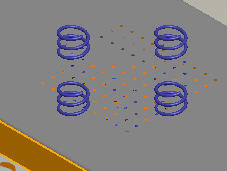

The center spring is located in a hole that has no washer, so it rests on the

surface of the chassis to which the housing is assembled. When the cover of the

chassis is installed, the four springs will protrude through the top of the

cover while the fifth spring (fully uncompressed) just touches the inside of the

top cover. (See Figure 2.)

Figure 2

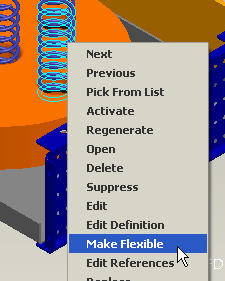

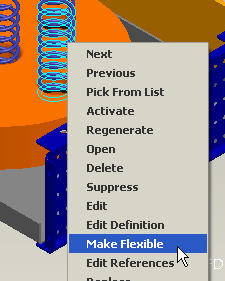

Compressing the four springs that are assembled to the outer holes on the

housing so that they just touch the inside of the top cover, can be accomplished

in Wildfire by making the springs "Flexible" components. Highlight one of the

springs that you wish to compress and click your right-mouse button. Select

Make Flexible from the pop-up menu. (See Figure 3.)

Figure 3

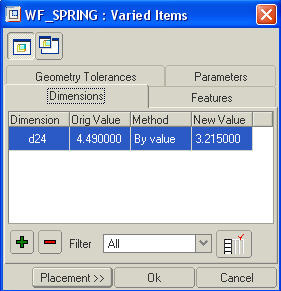

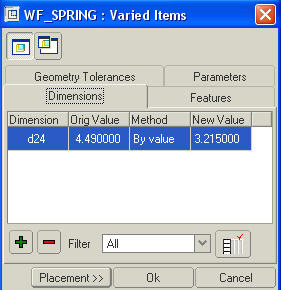

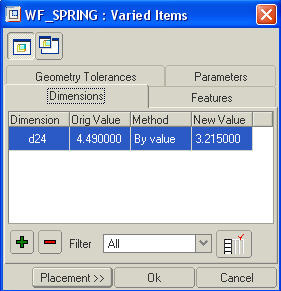

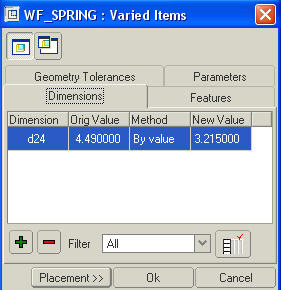

The Varied Items dialog box will appear. (See Figure 4.)

Figure 4

Select the green add button and use the Search Tool to find the

dimension in the spring that will allow it to be compressed. Select Apply

and select OK from the Select box. The dimension you selected will be

visible in the Varied Items box. (See Figure 5.)

Figure 5

Change New Value to allow the spring to just touch the inside of the top

cover and select Placement from the Varied Items dialog box. The

Component Placement dialog box will appear with a new button called Define

Flexibility. This button allows you to go back and modify the flexibility values

(varied items) of the spring. Select OK from the Component Placement

dialog box to complete the operation. The springs should be completely inside

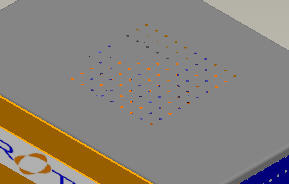

the top cover, as shown in Figure 6.

Figure 6

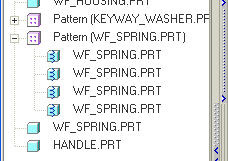

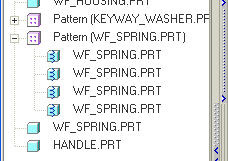

Inside the model tree, the four springs will have a new icon attached to them

indicating that they are flexible components. (See Figure 7.)

Figure 7

--Submitted by Stan Balish, president and chief executive officer, FroTime

Inc., San Diego, CA

How to Flatten a Harness Without the Network

(This tip can be applied in Wildfire in the Harness-MFG module.)

In previous releases, harness networks were flattened automatically with the

wires, cables or bundles in a flattened harness. The only way to remove the

network was to blank on a layer.

In Pro/ENGINEER Wildfire, the config.pro option "fan_with_network" has been

added and may be set to NO (default is YES) to exclude the network

from being flattened.

--Submitted by Florin Neamtu, principal engineer, PTC technical support,

Needham, MA

Determine What Materials to Use

When parts are in the early development stages, it is not always clear which

material to use. For example, 50 percent long glass polypropylene has a

different performance characteristic and density than 20 percent short glass.

Rather than modifying the Pro/ENGINEER part's density every time you want to

look at its total weight, you can write a relation to maintain as many options

as you wish. See below:

weight_material_1 = density * mp_volume("")

weight_material_2 = density * mp_volume("")

Substitute the material name and density values as needed. The "weight_material_*"

parameter then can be displayed as a parametric note on a drawing or used for

further calculations.

--Submitted by Steven J. Frey, vice president, Universal Parametrics, Inc.,

Ann Arbor, MI

Show a Mechanism Position on a Drawing

Under Drag Dialog, snapshot the mechanism position. Use the

make-available-in-drawing icon to make the snapshot visible in the drawing.

Create a new view or modify an existing view. Set the type as exploded. The

mechanism snapshots will be listed as an exploded state.

--Submitted by Ian Turner, design application support, CSC, MBDA UK Account,

Stevenage, UK

Drawing Snap Lines

Use snap lines to expedite drawing cleaning. A snap line is a line that shows up

on the screen but not on the printed drawing. It allows you to line up balloons,

notes or any draft entities that can be moved using the normal move command.

When an entity is selected and moved near the snap line, it snaps to it.

The moved entity will change colors when it is attached to the snap line. By

using the snap line, balloons can be lined up perfectly straight. The figure

below shows several balloons lined up on two snap lines.

Snap lines can be defined on individual drawings to locate dimensions, notes,

geometric tolerances, symbols and surface finishes. The system positions the

snap lines relative to the view outline, a selected model edge or datum plane.

After you place an item on a snap line, the item moves if the grid line moves

(such as when the view outline expands).

When placing and locating items on snap lines, keep the following two points in

mind:

- When you move an item onto one snap line, its color changes to magenta. If

you set the location by pressing the left-mouse button, the item snaps to the

snap line. Until you move the item again, the snap line determines its

location.

- If you move an item onto the intersection of two snap lines, the system

highlights one of the lines in red. If it snaps that item to more than one set

of snap lines at that location, you can navigate all possible sets using the

SEL SNAP LINE menu. When you choose Accept, the system locates the item on the

intersection of the two snap lines. When you move either snap line, the item

moves with it.

To Create a Snap Line:

- Select Insert >Snap Line on the menu bar.

- On the Menu Manager, do one of the following:

--Ed Muirhead, CAD systems administrator, Aberdeen, Scotland, UK.

2003/04/18

Q1- Vol. III, Issue 13

I am trying to model the shin guards (shown below) in Pro/ENGINEER, but I am

having trouble getting the shape to be correct. Can you recommend any advanced

tutorials or other training guides to help me solve this modeling problem?

--Andrew Walter, engineering student, Australian National University,

Canberra, ACT Australia

A1.1- Vol. III, Issue 13

The profile of the skin guard you show on the picture seems quite complex. It is

better to first digitize it using a laser digitizer or CMM. Afterward, bring the

digitized data into Pro/E.

--Yasir Arfeen, CAD/CAM engineer, OJ Pvt. Ltd., Karachi, Pakistan

A1.2- Vol. III, Issue 13

The best tutorials at student rates can be found at

www.frotime.com.

--G. Alexander Korentis, mechanical/biomedical engineer, QCI Engineering,

University of Connecticut, biomedical engineering doctoral student, Storrs, CT

A1.3- Vol. III, Issue 13

Take the "Advanced Surfacing Training" course offered by PTC or Rand.

--Chris Boyer, manager of product creation, Freudenberg Household Products

LP, Northlake, IL

A1.4- Vol. III, Issue 13

You might try looking into medical archives. If an FTP site exists for your

software, you may find proven applications there.

--Craig D. Skogerson, Indio, CA

Q2- Vol. III, Issue 13

I just received Pro/ENGINEER Wildfire and I am concerned about its stability. In

the past, I have heard it was wise to wait a few months before installing new

versions. Has anyone had problems with Wildfire and would you recommend I wait

until any possible bugs are worked out?

--Pascal Normand, designer, research and development, Industrial Handling

Division, IPL Inc., St-Damien, Quebec, Canada

A2.1- Vol. III, Issue 13

I've been using Wildfire for about a month and I have not come across any bugs

yet. I do stress yet. I have found it much better and easier to use than

R2001 once you get to know where everything is. An important addition is the

Menu Mapper under the Help menu. To find out how to do something in Wildfire,

open the Menu Mapper. The Menu Mapper shows an R2001 screen with the old-style

menu layout. After you run through the R2001 way of executing the command, using

the R2001 menus shown, the Menu Mapper will show you how to do it in Wildfire.

It is an excellent tool.

--Jeff Taylor, mechanical production engineer, Imagination Technologies Ltd.,

London, UK

A2.2- Vol. III, Issue 13

I installed Wildfire and just did my first real rush job with it. I took nine

hours nonstop and a large thermos of coffee. But I got it done. This was the

first time I used it. I have had no training on it. That speaks to its usability

and the fact that the interface has not changed a lot from the previous version.

However, Wildfire crashed four times doing routine tasks. Thankfully, no

critical steps were lost, and I was able to carry on. But it is definitely not

yet stable.

--Christopher J. Purcell, defense research and development, Canada Atlantic,

Dartmouth NS, Canada

A2.3- Vol. III, Issue 13

Wildfire does not work with Pro/INTRALINK.

--Tom Hargrove, fusion energy division, Oak Ridge National Laboratory, Oak

Ridge, TN

A2.4- Vol. III, Issue 13

You are right. Often it is better to wait for some builds after the first

production edition of a new Pro/E release. I have not tried Wildfire yet, but

I'll wait at least a couple of months before using it in a production

environment.

--Luca Armellin, mechanical engineer, Metelli SpA, Brescia, Italy

More Answers to Previous Questions

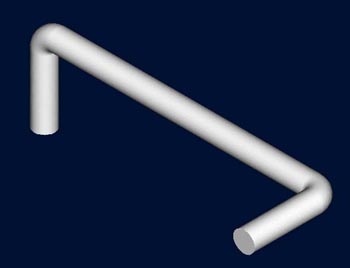

Q1- Vol. III, Issue 12

I have modeled a rod with two bends on two different planes. How do I unbend the

rod shown in the image below?

--Herb Spaulding, product engineer, Miller Industries, Ooltewah, TN

A1.1- Vol. III, Issue 12

Create a datum curve that follows the path you want. If it is a 2D path you want

to follow, you have to use the 2 Projections option in the Curve menu. Select

Insert >Datum >Curve and choose 2 Projections. If you choose two

datums at right angles to each other, they will create a datum curve where the

two intersect. You can then create a sweep. Select Create >Protrusion >Sweep

and choose Select Traj. Select the datum curve you have just selected and

sketch a round section. This technique can also be used to create sweeped pipes

in assemblies.

--Brian Middlemore, CAD support engineer, NCR Ltd., Dundee, Tayside, Scotland

Bar

Datum curve

A1.2- Vol. III, Issue 12

If you have modeled the rod with a toroidal bend tweak and you want to obtain a

straight workpiece, suppress the toroidal features.

--Zachary Popov, mechanical engineer, Technical University, Varna, Bulgaria

Q2- Vol. III, Issue 12

As of Pro/WILDFIRE, the internal datum plane, aka "on-the-fly" created datum

plane, functionality is removed. I am wondering if this will impair model

building?

--Alexander Fabre, B. Sc. M. E., Avalon Technology Stockholm AB, Sweden

A2.1- Vol. III, Issue 12

This functionality resides within the feature creation. While creating the

feature, click on the pause button at the bottom right of the screen. (It is

next to the preview button.) Create the necessary axes, planes, points etc, and

click on the pause button to continue building the feature. (Planes, axes,

points, etc. on the "fly").

--Roman Panov, MCAD application specialist, Engineering Data Resources AS,

Norway

A2.2- Vol. III, Issue 12

The "Make Datum" command is not necessarily removed, it has been restructured.

An "on-the-fly" datum still can be created by means of the same menu option for

creating a datum. The difference in Wildfire is that the "on-the-fly" datum

plane is an actual feature in the Model Tree and can be selected for reference

when creating other features. So "on-the-fly" datums are now more useful. The

only impairment is that users accustomed to the old menu selection have to learn

Wildfire's dashboard-style menu structure, which is easy to learn.

--Wes Gerber, mechanical design engineer, ITT Industries,

Aerospace/Communications Division, Fort Wayne, IN

A2.3- Vol. III, Issue 12

The internal datum plane functionality is not removed. It is accessed

differently. If you wish to create a datum on the fly, use the same icons or

menu picks as you would when creating "visible" datums. Datums created during

feature creation are listed in the model tree, but are automatically hidden and

grouped with the feature being created. In most cases the feature you are

creating - such as an extruded protrusion - will grab the plane you create and

use it for the sketching plane. If Wildfire does not select the created plane

automatically, then you can select it yourself. The important thing to note is

that on-the-fly datums are still with us.

--Kellie Wheatcroft, mechanical engineer, Smart Design, Perth, Western

Australia